-

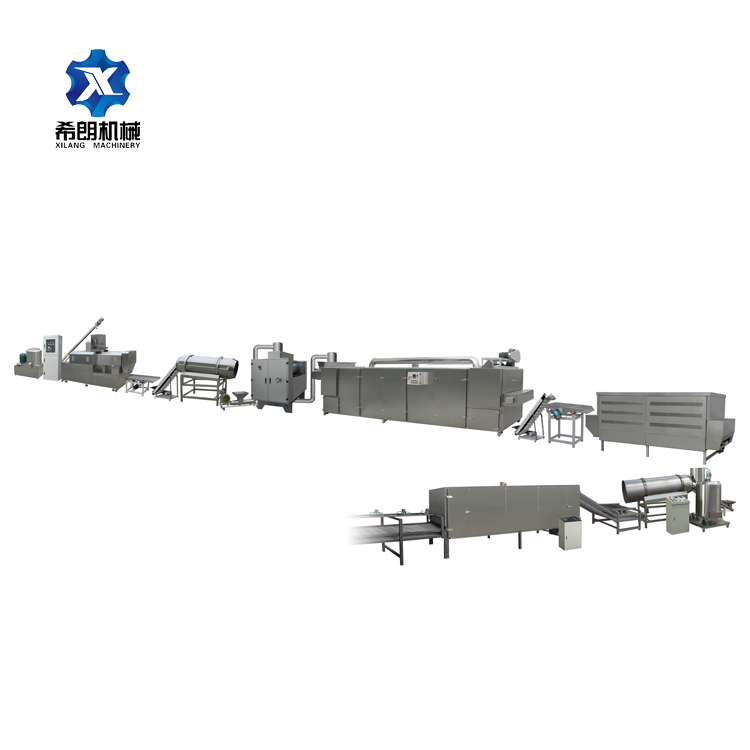

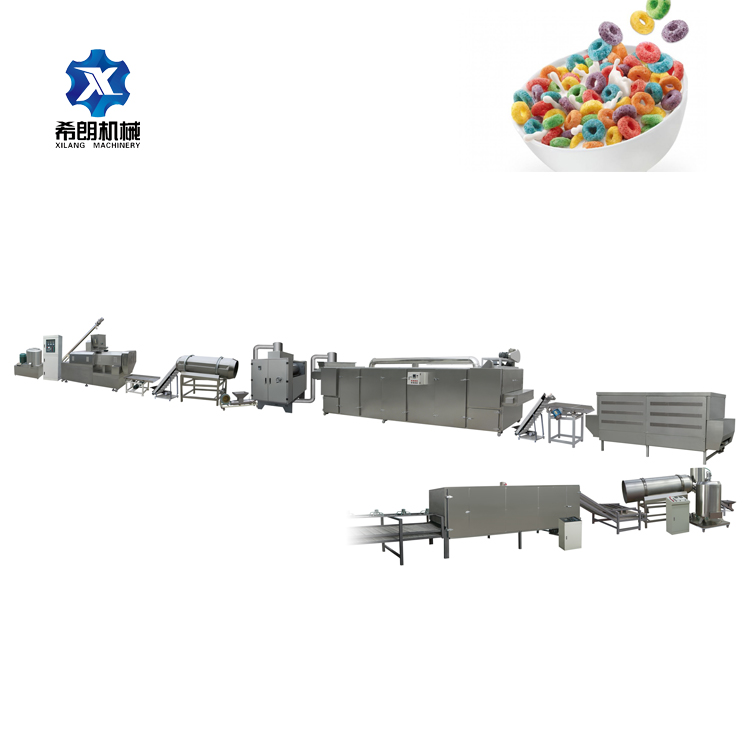

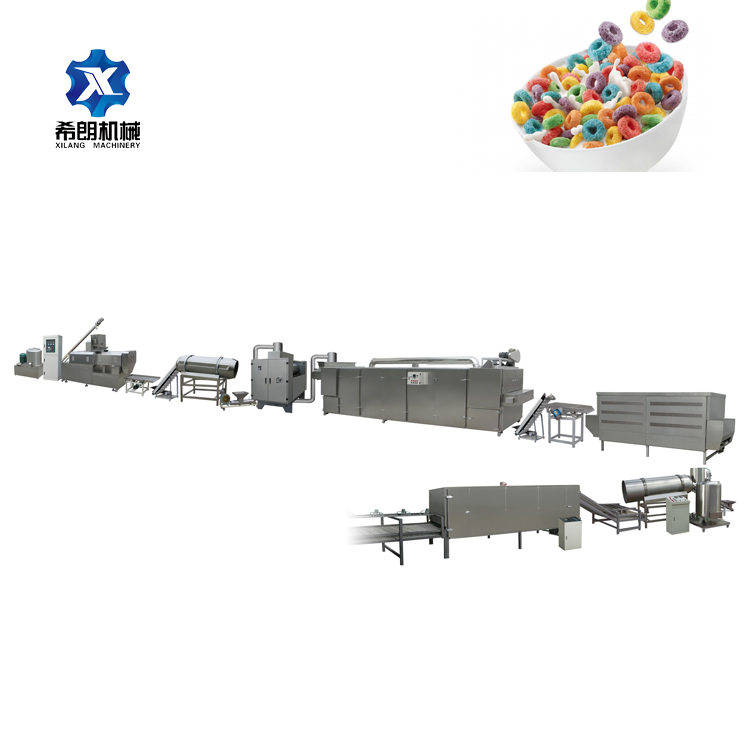

Cereal Corn Flakes Maker/Automatic Breakfast Cereal Making Machine

1) Ingredients: The ingredients of corn flakes are very important. The seasoning must ensure a good taste, especially the requirements for corn raw materials. It is directly related to whether high-quality corn flakes can be made, and the ratio of various nutrients. content. 2) Extrusion maturation molding: The extrusion maturation molding process of corn flakes is the key to producing high-quality corn flakes. The process of corn flakes must be fully matured without any puffing, only in this way can we make corn flakes that are dense, hard and crisp, with outstanding flavor.

Read More -

Breakfast Puffed Grain Machine|Corn Flakes Production Line

1) Ingredients: The ingredients of corn flakes are very important. The seasoning must ensure a good taste, especially the requirements for corn raw materials. It is directly related to whether high-quality corn flakes can be made, and the ratio of various nutrients. content. 2) Extrusion maturation molding: The extrusion maturation molding process of corn flakes is the key to producing high-quality corn flakes. The process of corn flakes must be fully matured without any puffing, only in this way can we make corn flakes that are dense, hard and crisp, with outstanding flavor.

Read More -

Automatic Cereal Corn Flakes Production Line

1) Ingredients: The ingredients of corn flakes are very important. The seasoning must ensure a good taste, especially the requirements for corn raw materials. It is directly related to whether high-quality corn flakes can be made, and the ratio of various nutrients. content. 2) Extrusion maturation molding: The extrusion maturation molding process of corn flakes is the key to producing high-quality corn flakes. The process of corn flakes must be fully matured without any puffing, only in this way can we make corn flakes that are dense, hard and crisp, with outstanding flavor.

Read More -

Instant Breakfast Cereal Corn Flake Production Line

1. Process: the cooking method of granular materials is changed to the extrusion method of powder materials, and the advanced twin-screw extruder is used for fully kneading, cooking and cutting, pressing and forming of the grain powder after adding water. 2. Technology: high degree of automation, whole process control, easy to operate. Assembly line continuous production, high efficiency, low noise, energy saving and stability. 3. Products: the breakfast cereal production line of corn flakes, cereal, cheerie, puffed rice and other breakfast cereals retain the nutritional ingredients of cereals in good condition; The product can be mixed with hot coffee, hot milk, or eaten as a snack.

Read More -

Breakfast Cereal Corn Flakes Production Manufacturing Equipments

Breakfast cereal food is one popular breafast cereal food which is processed by this line using grain corn as basic material,the following are main introduction which help you know this kind of machine well. 1)corn flakes manufacturing plant Ingredients: corn flakes manufacturing plantingredients of corn flakes are very important. The seasoning must ensure a good taste, especially the requirements for corn raw materials. It is directly related to whether high-quality corn flakes can be made, and the ratio of various nutrients. content. 2) corn flakes manufacturing plant Extrusion maturation molding: The extrusion maturation molding process of corn flakes is the key to producing high-quality corn flakes. The process of corn flakes must be fully matured without any puffing, only in this way can we make corn flakes that are dense, hard and crisp, with outstanding flavor.

Read More -

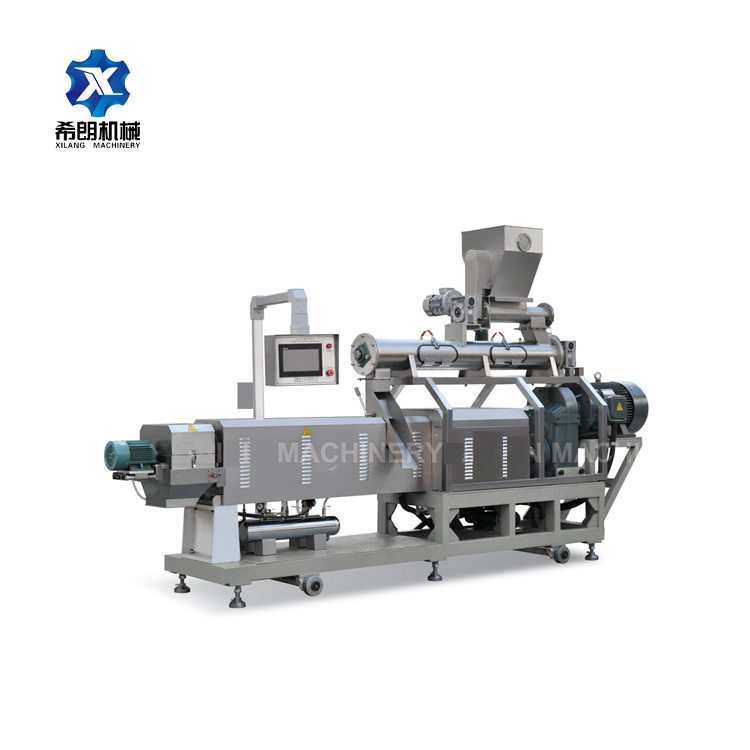

Breakfast Cereal Crispy corn flakes Extruder Machine

1. Xilong automatic breakfast corn flakes production line, the whole assembly line is reasonably matched, and can realize the whole process control, strong power operation and stable operation 2. The production line has a simple process and convenient operation.With corn, wheat, oats and other grains as raw materials, through the double screw extruder to achieve cooking, granulation, and then through pressing slices, baking, spraying and other processes, you can make raw, sweet, salty crisp ready-to-eat breakfast cornflakes food; 3. The production line adopts the advanced double-screw extrusion technology, instead of the traditional pressure roller adhesive, which can fully retain the nutrients in the grain. The production line can also produce breakfast grain food of various shapes.

Read More -

Granule breakfast Corn Flake production line

1) Ingredients: The ingredients of corn flakes are very important. The seasoning must ensure a good taste, especially the requirements for corn raw materials. It is directly related to whether high-quality corn flakes can be made, and the ratio of various nutrients. content. 2) Extrusion maturation molding: The extrusion maturation molding process of corn flakes is the key to producing high-quality corn flakes. The process of corn flakes must be fully matured without any puffing, only in this way can we make corn flakes that are dense, hard and crisp, with outstanding flavor.

Read More -

Multi-function automatic kelloggs corn flakes manufacturing machine

1) Ingredients: The ingredients of corn flakes are very important. The seasoning must ensure a good taste, especially the requirements for corn raw materials. It is directly related to whether high-quality corn flakes can be made, and the ratio of various nutrients. content. 2) Extrusion maturation molding: The extrusion maturation molding process of corn flakes is the key to producing high-quality corn flakes. The process of corn flakes must be fully matured without any puffing, only in this way can we make corn flakes that are dense, hard and crisp, with outstanding flavor.

Read More -

Fully Automatic Small Corn Flakes Making Machine

1) Ingredients: The ingredients of corn flakes are very important. The seasoning must ensure a good taste, especially the requirements for corn raw materials. It is directly related to whether high-quality corn flakes can be made, and the ratio of various nutrients. content. 2) Extrusion maturation molding: The extrusion maturation molding process of corn flakes is the key to producing high-quality corn flakes. The process of corn flakes must be fully matured without any puffing, only in this way can we make corn flakes that are dense, hard and crisp, with outstanding flavor.

Read More -

Breakfast Cereal Corn Flake Processing line

Breakfast cereal corn flake processing machine is a new type of fast food, long storage time, easy to carry, not only can be eaten directly, but also can be processed into other foods. Can be mixed with cold milk and yogurt for breakfast Corn flakes are the most common cereal snack food in the world. The raw material for processing corn flakes is best to choose hard dent corn, because of its high horny endosperm content, high transparency after starch gelatinization, and good product appearance. When eating, prepare corn flakes granules with boiling water. If corn flakes are put into the prepared soup, it can be made into corn flake soup.

Read More

Get the latest price? We'll respond as soon as possible(within 12 hours)