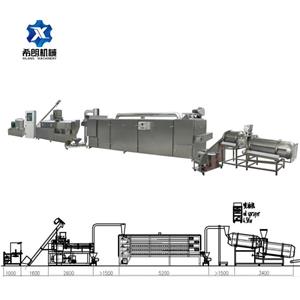

1 bugles snack making machines are made by stainless steel, this line is with reasonable design and with high automation; 2 the screws of puff frying snack production line are made by alloy steel, with building block system structure and self-cleaning function 3 Raw material of bugles snack making machine: Wheat flour, potato starch, potato flour, corn starch, cassava starch and so on. 4.After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

Read More

1 bugles snack making machines are made by stainless steel, this line is with reasonable design and with high automation; 2 the screws of puff frying snack production line are made by alloy steel, with building block system structure and self-cleaning function 3 Raw material of bugles snack making machine: Wheat flour, potato starch, potato flour, corn starch, cassava starch and so on. 4.After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

Read More

1 bugles snack making machines are made by stainless steel, this line is with reasonable design and with high automation; 2 the screws of puff frying snack production line are made by alloy steel, with building block system structure and self-cleaning function 3 Raw material of bugles snack making machine: Wheat flour, potato starch, potato flour, corn starch, cassava starch and so on. 4.After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

Read More

1) Ingredients: The ingredients of corn flakes are very important. The seasoning must ensure a good taste, especially the requirements for corn raw materials. It is directly related to whether high-quality corn flakes can be made, and the ratio of various nutrients. content. 2) Extrusion maturation molding: The extrusion maturation molding process of corn flakes is the key to producing high-quality corn flakes. The process of corn flakes must be fully matured without any puffing, only in this way can we make corn flakes that are dense, hard and crisp, with outstanding flavor.

Read More

1. Xilang small instant noodle production line has novel design, compact structure, perfect technology and stable and reliable performance. Moderate production capacity, small footprint, small investment. 2. The mini instant noodle making machine from flour to finished product is completed at one time, with high degree of automation and easy to learn. 3. The mini instant noodle processing machine has some advantages: short rehydration time, good elasticity, smooth and transparent, the quality of corrugated instant noodles can be comparable with that of traditional large-scale equipment products.

Read More

1 bugles snack making machines are made by stainless steel, this line is with reasonable design and with high automation; 2 the screws of puff frying snack production line are made by alloy steel, with building block system structure and self-cleaning function 3 Raw material of bugles snack making machine: Wheat flour, potato starch, potato flour, corn starch, cassava starch and so on. 4.After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

Read More

1.The dog food pellet extrusion machine manufacturing equipments adopt internationally advanced twin screw extrusion technology. 2.The dog food pellet extrusion machine manufacturing equipments have advantages of small investement,high output ,small floor area etc.

Read More

1.The dog food pellet extrusion machine manufacturing equipments adopt internationally advanced twin screw extrusion technology. 2.The dog food pellet extrusion machine manufacturing equipments have advantages of small investement,high output ,small floor area etc.

Read More

1.The dog food pellet extrusion machine manufacturing equipments adopt internationally advanced twin screw extrusion technology. 2.The dog food pellet extrusion machine manufacturing equipments have advantages of small investement,high output ,small floor area etc.

Read More

1.The dog food pellet extrusion machine manufacturing equipments adopt internationally advanced twin screw extrusion technology. 2.The dog food pellet extrusion machine manufacturing equipments have advantages of small investement,high output ,small floor area etc.

Read More

1.The dog food pellet extrusion machine manufacturing equipments adopt internationally advanced twin screw extrusion technology. 2.The dog food pellet extrusion machine manufacturing equipments have advantages of small investement,high output ,small floor area etc.

Read More

1.The floating fish feed processing machine line can make kinds of feed for different fish, such as fish, catfish, shrimps, crab, etc. 2.Extruder for fish feed production process is deliberately made for special feed, which needs high in-shape rate and good-looking appearance. 3.High Efficiency,the floating fish feed processing machine line Low electricity and labor consumption,

Read MoreOur customers sent us feedback on the use of the machine and were satisfied with the product results.