-

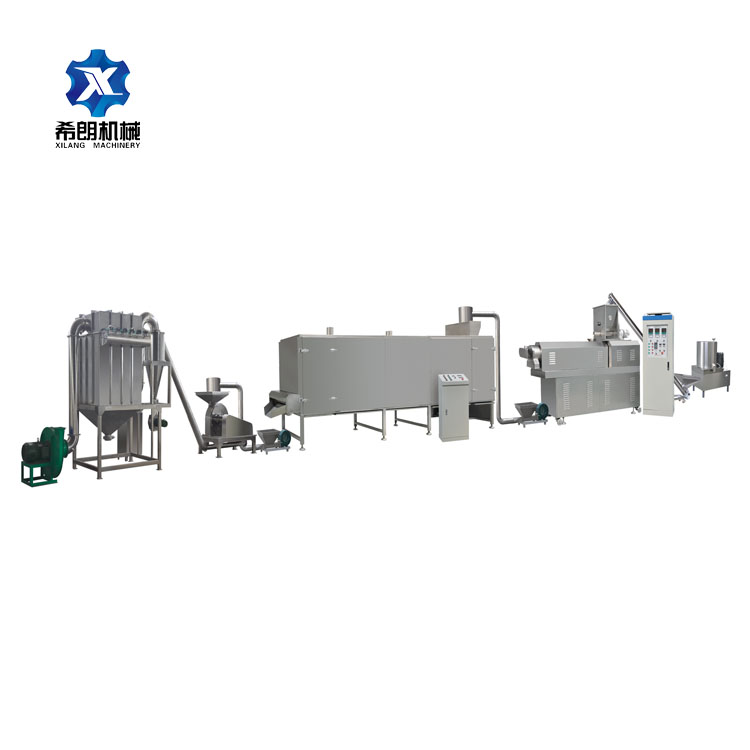

Food Grade material Baby food Rice Flour Making Machine

1. The puffed nutrition powder production line adopts double screw extrusion and expansion technology, replacing the traditional new rice noodle cooking technology. 2. Microwave curing solves the problem of oil-based and high-fiber products.Microwave oven can be dry, mature and disinfection, a machine to save costs. 3. The Xilpuffed nutrition powder production line has high degree of automation, strong stability, simple operation, short process time and high yield.

Read More -

Industrial Nutritional Powder Infant Flour Maker Instant Porridge Baby Food Making Machine

1. The puffed nutrition powder production line adopts double screw extrusion and expansion technology, replacing the traditional new rice noodle cooking technology. 2. Microwave curing solves the problem of oil-based and high-fiber products.Microwave oven can be dry, mature and disinfection, a machine to save costs. 3. The Xilpuffed nutrition powder production line has high degree of automation, strong stability, simple operation, short process time and high yield.

Read More -

Nutritional infant instant Baby Powder Food Extruder Making Machine

Nutrition powder processing line 1. Technical aspects: Xilang company's expansion powder production line adopts double-screw extrusion and expansion technology to replace the traditional new technology of cooking rice noodles production. 2. Operation: The nutritional rice flour production line of Xilang Company is integrating mixing, cooking, ripening, expansion, sterilization, mixing and packaging, and there is no boiler. The production process is simplified, efficient and environmental protection 3. Application: The expansion host adopts domestic high-efficiency double screw extrusion and expansion technology, with screw segmented combination structure, which can meet the expansion processing needs of different grain raw materials. The raw materials can be a single material of rice flour and corn flour, but also its mixture 4. Product aspects: Changing raw materials and auxiliary equipment can change the product and produce different flavors of nutritional powder

Read More -

Commercial Nutritional Powder Infant Flour Maker Instant Porridge Baby Food Making Machine

1. The puffed nutrition powder production line adopts double screw extrusion and expansion technology, replacing the traditional new rice noodle cooking technology. 2. Microwave curing solves the problem of oil-based and high-fiber products.Microwave oven can be dry, mature and disinfection, a machine to save costs. 3. The Xilpuffed nutrition powder production line has high degree of automation, strong stability, simple operation, short process time and high yield.

Read More -

Full Automatic Instant Nutrition Protein Powder Production Line Baby Food Powders Making Machine

1. The puffed nutrition powder production line adopts double screw extrusion and expansion technology, replacing the traditional new rice noodle cooking technology. 2. Microwave curing solves the problem of oil-based and high-fiber products.Microwave oven can be dry, mature and disinfection, a machine to save costs. 3. The Xilpuffed nutrition powder production line has high degree of automation, strong stability, simple operation, short process time and high yield.

Read More -

Complete line Nutritional cereals rice powder baby food processing equipment making machine

1. The puffed nutrition powder production line adopts double screw extrusion and expansion technology, replacing the traditional new rice noodle cooking technology. 2. Microwave curing solves the problem of oil-based and high-fiber products.Microwave oven can be dry, mature and disinfection, a machine to save costs. 3. The Xilpuffed nutrition powder production line has high degree of automation, strong stability, simple operation, short process time and high yield.

Read More -

Nutritional cereals rice powder baby food processing equipment making machine

1. The puffed nutrition powder production line adopts double screw extrusion and expansion technology, replacing the traditional new rice noodle cooking technology. 2. Microwave curing solves the problem of oil-based and high-fiber products.Microwave oven can be dry, mature and disinfection, a machine to save costs. 3. The Xilpuffed nutrition powder production line has high degree of automation, strong stability, simple operation, short process time and high yield.

Read More -

High Quality and Industrial Nutrition Powder Production China factory supply

1. The puffed nutrition powder production line adopts double screw extrusion and expansion technology, replacing the traditional new rice noodle cooking technology. 2. Microwave curing solves the problem of oil-based and high-fiber products.Microwave oven can be dry, mature and disinfection, a machine to save costs. 3. The Xilpuffed nutrition powder production line has high degree of automation, strong stability, simple operation, short process time and high yield.

Read More -

Industrial High capacity Nutritional Rice Powder Making Machine Processing Line

1. The puffed nutrition powder production line adopts double screw extrusion and expansion technology, replacing the traditional new rice noodle cooking technology. 2. Microwave curing solves the problem of oil-based and high-fiber products.Microwave oven can be dry, mature and disinfection, a machine to save costs. 3. The Xilpuffed nutrition powder production line has high degree of automation, strong stability, simple operation, short process time and high yield.

Read More -

double extruded breakfast baby infant grain instant cereal nutritional powder food making machine

Nutrition powder processing line 1. Technical aspects: Xilang company's expansion powder production line adopts double-screw extrusion and expansion technology to replace the traditional new technology of cooking rice noodles production. 2. Operation: The nutritional rice flour production line of Xilang Company is integrating mixing, cooking, ripening, expansion, sterilization, mixing and packaging, and there is no boiler. The production process is simplified, efficient and environmental protection 3. Application: The expansion host adopts domestic high-efficiency double screw extrusion and expansion technology, with screw segmented combination structure, which can meet the expansion processing needs of different grain raw materials. The raw materials can be a single material of rice flour and corn flour, but also its mixture 4. Product aspects: Changing raw materials and auxiliary equipment can change the product and produce different flavors of nutritional powder

Read More -

infant instant porridge nutritional powder baby food processing machine line

Nutrition powder processing line 1. Technical aspects: Xilang company's expansion powder production line adopts double-screw extrusion and expansion technology to replace the traditional new technology of cooking rice noodles production. 2. Operation: The nutritional rice flour production line of Xilang Company is integrating mixing, cooking, ripening, expansion, sterilization, mixing and packaging, and there is no boiler. The production process is simplified, efficient and environmental protection 3. Application: The expansion host adopts domestic high-efficiency double screw extrusion and expansion technology, with screw segmented combination structure, which can meet the expansion processing needs of different grain raw materials. The raw materials can be a single material of rice flour and corn flour, but also its mixture 4. Product aspects: Changing raw materials and auxiliary equipment can change the product and produce different flavors of nutritional powder

Read More -

infant instant Baby Powder Food Extruder Making Machine

Nutrition powder processing line 1. Technical aspects: Xilang company's expansion powder production line adopts double-screw extrusion and expansion technology to replace the traditional new technology of cooking rice noodles production. 2. Operation: The nutritional rice flour production line of Xilang Company is integrating mixing, cooking, ripening, expansion, sterilization, mixing and packaging, and there is no boiler. The production process is simplified, efficient and environmental protection 3. Application: The expansion host adopts domestic high-efficiency double screw extrusion and expansion technology, with screw segmented combination structure, which can meet the expansion processing needs of different grain raw materials. The raw materials can be a single material of rice flour and corn flour, but also its mixture 4. Product aspects: Changing raw materials and auxiliary equipment can change the product and produce different flavors of nutritional powder

Read More

Get the latest price? We'll respond as soon as possible(within 12 hours)