Corn Puffs Snack Food Extruder Machine

Brand :XI LANG

Product origin :Jinan,China

Delivery time :20days

Supply capacity : 100 sets per month

1.Adopting advance twin screw extrusion technology.

2.Converter( used to control the speed of the main motor , feeding system and cutting system ) brand can be Delta,Pioneer,CHNT or Schneider. All the electric device brand can be customized as you need.

3.Provide Free spare parts After-sales , Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

4.Machine material generally is Food grade stainless steel, also can customized as require.

5.Guarantee Time is 2 year.

1.Product Description of corn puffs extruder machine

1.1.Brief Introduction

Puffed Snack food production line adopts advanced extrusion technology. In the extruder the ingredients are cooked under intense heat and pressure. At the extruder exit, molding dies and cutting tools equipped. The expanded products can obtain various sizes and shapes by changing molds and cutter.

1.2. Raw material of corn puffs extruder machine

Adopt corn, rice, wheat, oat, barley etc as material to produce various tyype puffs snacks.

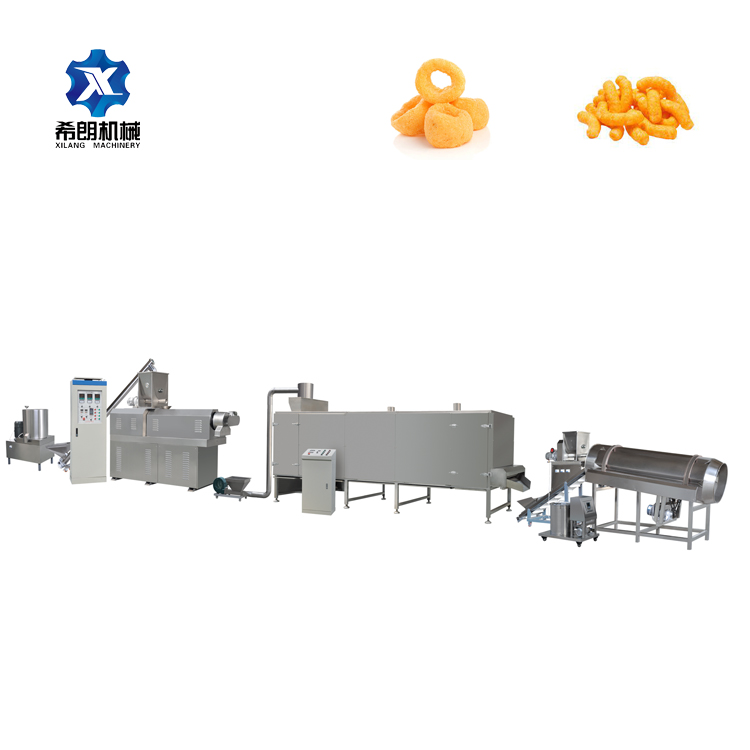

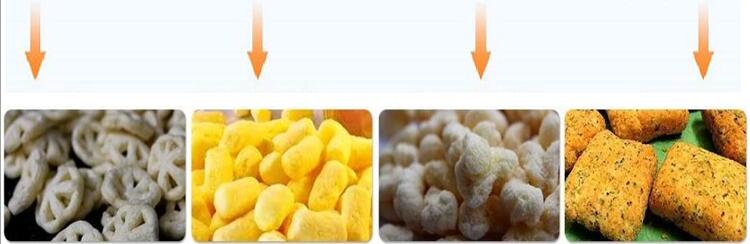

1.3. Products:

A wide range of puff snacks can be produced like ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

2.The technical specification of corn puffs extruder machine

Model | XL65 twin screw extrude line | XL70 twin screw extrude line | XL85 twin screw extrude line |

Installed power | 72kw | 95kw | 150kw |

Actual consumption power | 50kw | 70kw | 110kw |

Production capacity | 100-150kg/h | 200-300kg/h | 350-500kg/h |

Appearance size | 16000x1600x2300mm | 17600x1600x2300mm | 20000x1600x3500mm |

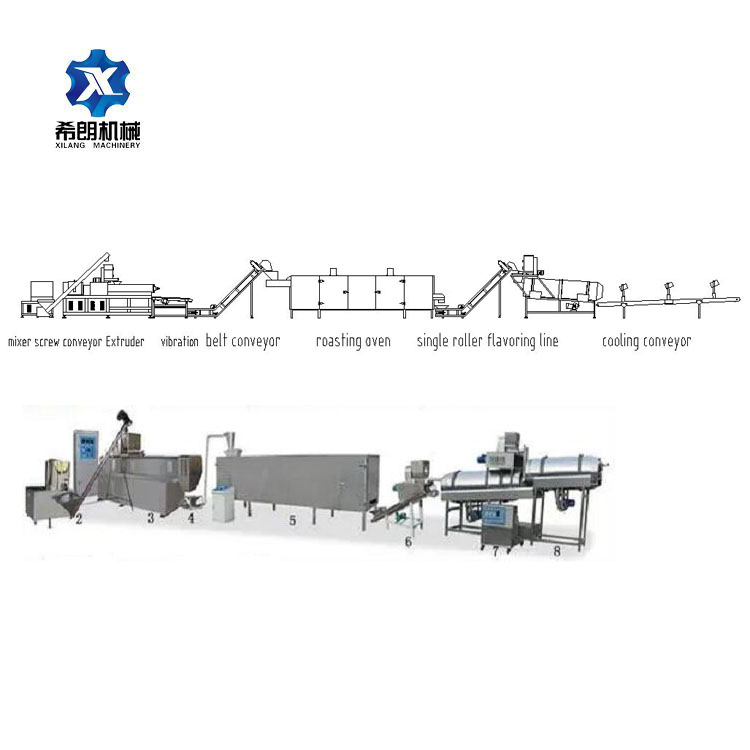

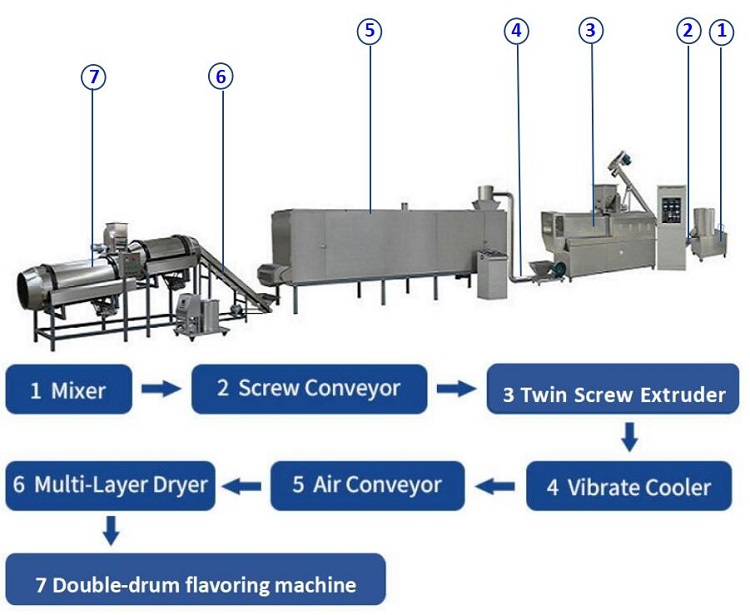

3.Flow Chart of puffed corn snacks making production line

1.Powder mixer- 2.Screw conveyor -3. Double screw extruder - 4. Air conveyor - 5. Oven -6. Hoister- 7. seasoning Machine- 8.Pckaging machine

4.Items of puffed corn snacks maker machine

NO. | Machine Name | Function |

1 | Mixer | Mix the raw material and other additives fully. |

2 | Screw conveyor | Screw turns to make the raw material convey in the sealed tube,no leaking and no pollution |

3 | Twin screw Extruder | The material is fully matured under high temperature and pressure, through the outlet mold expansion, form foods of various shapes. |

4 | Air Conveyor | conveys the food relying on the wind-force from the blower |

5 | Muti-layer Dryer | Used to bake and dry food, Net belt running speed can be controlled |

6 | Hoist | Convey the products into flavoring machine |

7 | Double rolls flavoring line | The stainless steel flavor feeder is used to spray flavor to the drum |

5.Sample Photos

6.Main machines details

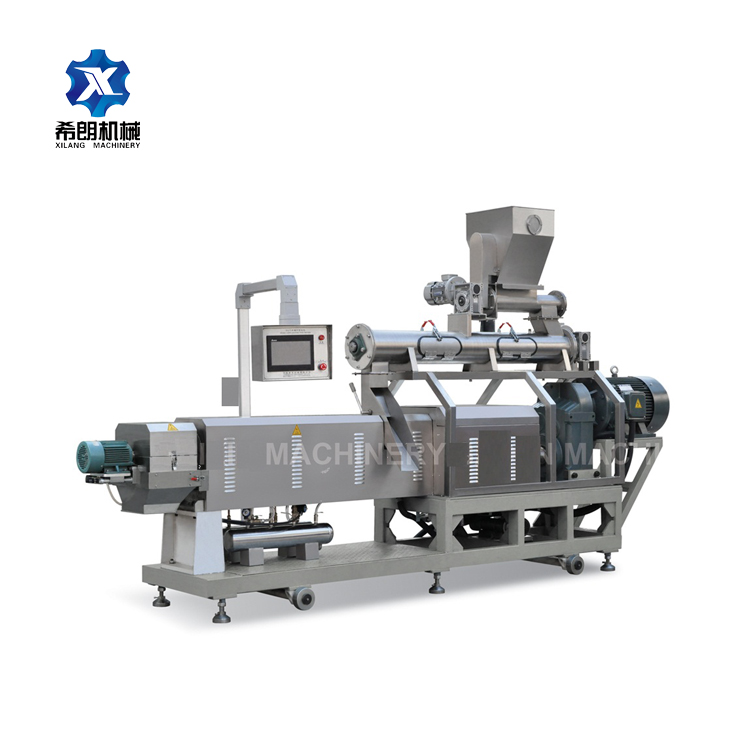

6.1.The main twin screw extruder of Snacks Corn Puffs Extruder Machine

a.The main extruder of Corn Puffs Extruder Machine is made up of feeding system, heating system, extrusion system and cutting system. The main system of automatic full line snack puff make machine adopts frequency speed with high automation controlling.

b.The screws of Corn Puffs Extruder Machine are made of the special alloy steel (38CrMoAl)which has the advantage of durable usage, high pressure,and longer life.

c.The forced lubrication system of puff rice snack making machine can guarantee the equipment transmission life longer.

e.Auto-temperature control system and self-cleaning of automatic full line snack puff make machine makes it more convenient.

f.automatic full line snack puff make machine has the widest range of applications and can produce different products with different equipment and models.

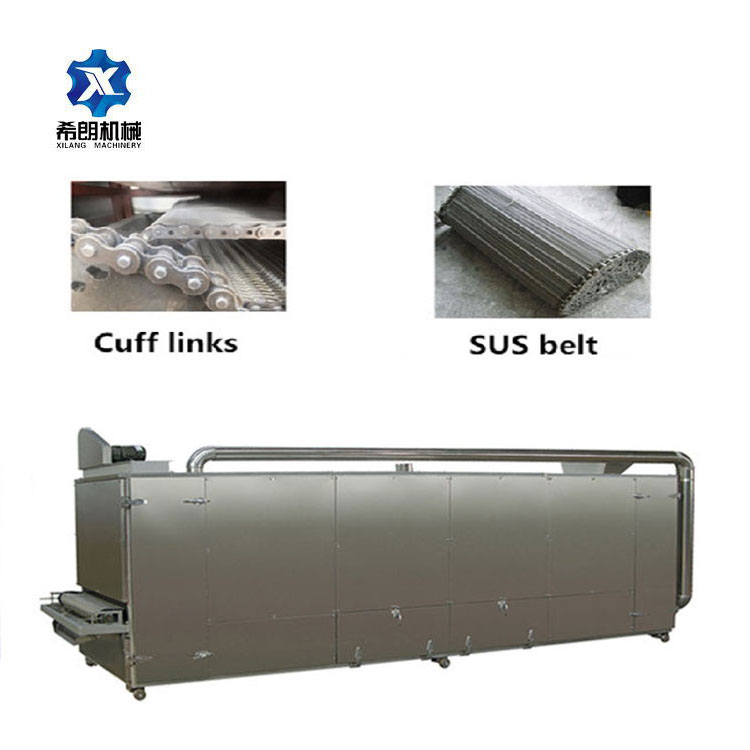

6.2.Muti-layer Dryer of Corn Puffs Extruder Machine line

b.Dryer is compact, has small dry area and a large superficial area. It also features small scale of heat elimination and high thermal efficiency.

c.Mesh belt conveyors and thermal insulation boards all use stainless steel material, making the equipment clean and sanitary.

d. The speed of mesh belt conveyor is adjustable, the drying period for food in the oven can be adjusted.

e. The automatic temperature control system makes it possible to set the temperature according to your needs.

7.Packaging and transportation

1).Packaging: daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film. Finally pack them with wooden case.

2)Customer's requirement is available.

3).If you want to know the transportation cost: by air-please tell me your airport name; by express-please tell me your detailed address(including zip code, house number, street, city, country); by ship-please tell me your delivery port.

8.Company profile:

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

9.FAQ

Q1: Are you a trade company or a manufacturer?

A1:We are a manufacturer,we have own factory and R&D department.

SGS has certified our company on site.welcome to visit our factory and check the machines.

Q2: How long is your delivery time?

A2: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q3: Could you supply all the parameters about the machines?

A3: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q4. Can you provide food or feed formula?

A4: We can provide basic formula for produce the food etc.

And help customer to produce new products according to customer’s formula.

Q5: What is your terms of payment ?

A5: 30% T/T in advance ,70% balance before shippment after inspection.

Q6: How about the after-service?

A6: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators.