cartoon pasta production line

Brand :XI LANG

Product origin :Jinan,China

Delivery time :20days

Supply capacity : 100 sets per month

Easy-to-cook food supplement star noodles for children produced by processing machinery for children’s supplementary food star noodles are cute in shape, attracting children’s attention and driving the baby’s appetite. In addition, star noodles do not contain preservatives. The main nutrients include protein and carbohydrates, which are suitable for babies’ delicate intestines and stomachs. Good absorption, good digestion.

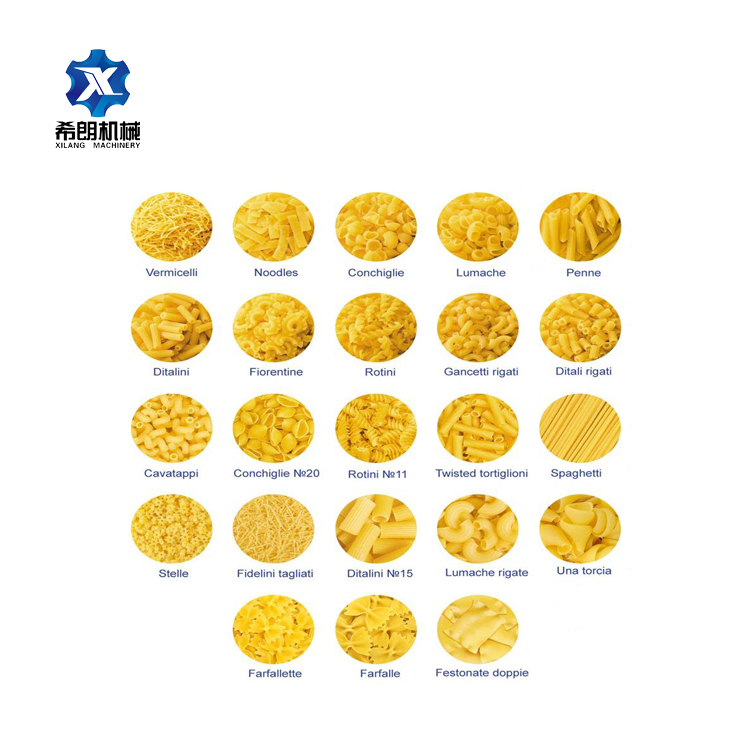

Easy-to-cook supplementary food star noodle processing machine. The production line has reasonable design, high degree of automation and accurate control of extrusion parameters. The host is equipped with high and low pressure spirals, which increases the use of raw materials, reduces costs, and improves product quality. The equipment has multiple functions in one machine, complete products, various patterns, and can produce long and short products.

Granular noodles, star noodles, also known as grain noodles, pearl noodles, are noodles with a variety of colors and are a kind of complementary noodles for infants and young children. More and more mature manufacturers will add corresponding nutrients during the processing process according to the physical development needs of Chinese babies and children. With the continuous development of the noodle supplement processing industry, the star-shaped noodles produced by the Xilang machinery granular noodle production line have won a good reputation in terms of taste and nutrition. With the advanced technology, Xilang has cooperated with many domestic brands. Based on the traditional advantages of noodle supplements, breakthrough innovations have allowed infants and young children to experience more fresh and nutritious granular noodles.

The technical specification of machine:

The main mac hine power | Output | The main machine size | |

100 single screw production line | 45kw | 120-180kg/h | 2900*1000*1900mm |

75 twin screw production line | 90kw | 200-300kg/h | 5000*1200*2400mm |

Process flow and equipment composition:

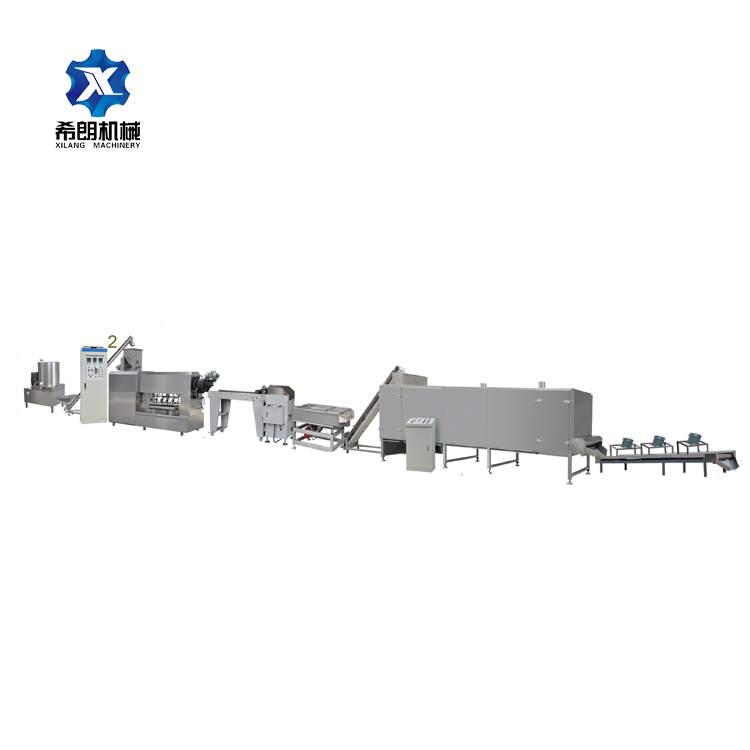

1. The machine is composed of feeding system, extrusion system, rotary cutting system, heating system, transmission system, cooling system and control system.

2. Adopt advanced frequency conversion technology to make the equipment run more smoothly and save electricity;

3. The screw adopts alloy steel nitriding treatment, and the screw life is long;

4. Process flow: raw material preparation→mixing→extrusion molding→transportation→drying→finished product→(packaging)

5. Equipment configuration: powder mixer → feeding machine → extruder → conveyor elevator → oven → (packing machine)

Technical formula and process composition:

1) Flour mixing machine: separate rice noodles or mix some additives, add a certain amount of water and mix well.

2) Feeding machine: The motor is used for screw conveying, and the mixed raw materials are conveyed to the feeding hopper of the extruder to ensure convenient and fast feeding.

3) Extruder: There is a special control cabinet, which can extrude rice particles in a high-pressure environment, adjust the process and change the mold to produce rice particles of different shapes.

4) Vibrating screen: The extruded particles contain a little temperature and viscosity, and the particles are spread out through the vibrating screen to avoid sticking together.

5) Air conveyor: convey the product to the oven, and the height of the hoist is determined according to the oven.

6) Multi-layer oven: most ovens are electric ovens, the temperature is adjusted between 0-200 degrees through the control cabinet, the inside is a stainless steel double-layer mesh bag, the baking time can be adjusted according to the speed, minus the particle moisture, and increase the shelf life ;

7) Cooling conveyor: the dried particles contain a certain temperature, and the packaging quality can be guaranteed by cooling to room temperature.

8) Packaging machine: vertical packaging machine and combined computer weighing and packaging machine can be used.

Product quality control:

(1) Design and control technicians carry out scientific and reasonable design according to the specific requirements of users and the actual conditions of the test, and prepare process cards for the entire process of equipment manufacturing.

(2) Purchasing control establish a list of suppliers, conduct strict inspections and comparisons with suppliers, follow the principle of high quality, establish supplier files, and purchase outsourced parts of the same variety, and there should be no less than three suppliers that can normally supply .

(3) Production control. Production must be based on technical documents. The processed qualified products of each process must be marked, and the key parts must be clearly marked to ensure the traceability of the product.

(4) Inspection control

● Appoint full-time inspectors to inspect the raw materials and outsourcing and outsourcing components. When the batch is large, random inspections can be carried out, but the random inspection shall not be less than 30%. The key, precise outsourcing parts must be all inspected.

●The processing of self-made parts must undergo self-inspection, mutual inspection, re-inspection, and general inspection. All qualified products can be regarded as qualified products.

●If the finished product can be installed in the factory and started for testing, it must be tested in the factory and the test machine can be inspected before it can leave the factory; if it cannot be installed in our factory, the components of the equipment must be strictly inspected in stages, in the buyer's factory After the installation is completed and the test machine is successful, the machine can produce materials normally.

Jinan Xilang Machinery Co., Ltd. is an extruder, twin-screw extruder, single-screw extruder, breakfast cereal instant food (corn flakes, nutritional powder) production line, leisure (fried, sandwich) snack food production line, pet feed , Fishing bait production line, tissue protein production machinery, modified starch production line, bread crumb production line, experimental twin-screw extruder, reconstituted nutritious rice production line, industrial microwave drying and sterilization equipment, electromagnetic drying tunnel oven and packaging machinery research, development, and production , A manufacturer integrating sales.

The company is located in Jinan, the spring city of Shandong. The company has strong design strength, advanced production equipment and rich manufacturing experience. Through the continuous efforts of our company in the past eight years, it has a group of high-quality engineering design and food technology talents, and dedication to good extruding technology results. To you, high efficiency, high quality and high performance constitute our core competition.

?Jinan Xilang Machinery Company warmly welcomes users from all walks of life to inquire, visit and negotiate on site! We serve you wholeheartedly!