Edible rice drinking straw processing mahicne

Brand :XI LANG

Product origin :Jinan,China

Delivery time :20days

Supply capacity : 100 sets per month

1. Technology: Xilang rice straw production line has reasonable design, high degree of automation, accurate extrusion parameters control, the host is equipped with high and low pressure screw, which increases the use of raw materials and reduces the cost. The product quality is higher, the variety is more diverse.

2. Process: The production process is simple, a twin screw puffing machine can complete the process of mixing and rubbing, cooking, extrusion molding, made of various sizes of billets, and then drying can be made into smooth surface, realistic shape straw;

3. Products: by adjusting the forming mold and ingredients, edible straws with novel shapes and rich colors can be produced. The appearance of the straw is not different from ordinary straw, the surface is sandy texture, strong and flexible.

Brief introduction edible straw making machine :

Environmental protection rice straw production line mainly adopt rice, tapioca rice flour as raw materials, using a unique extrusion process to produce various shapes products. It can soak 5-8 hours in cold drinks and 2-3 hours in hot drinks without affecting the taste of drinks to meet the needs of various drinks. The straw produced by the edible straw making machine can be quickly and completely degraded, green and pollution-free,which could meet the requirements of environmental laws and regulations of many countries.

The technical specification of edible straw making machine

Model | EXT100 | TSE75 |

Installed power | 100kw | 200kw |

Production capacity | 100-150kg/h | 200-300kg/h |

Appearance size | 50000*2000*2200mm | 60000*2000*2600mm |

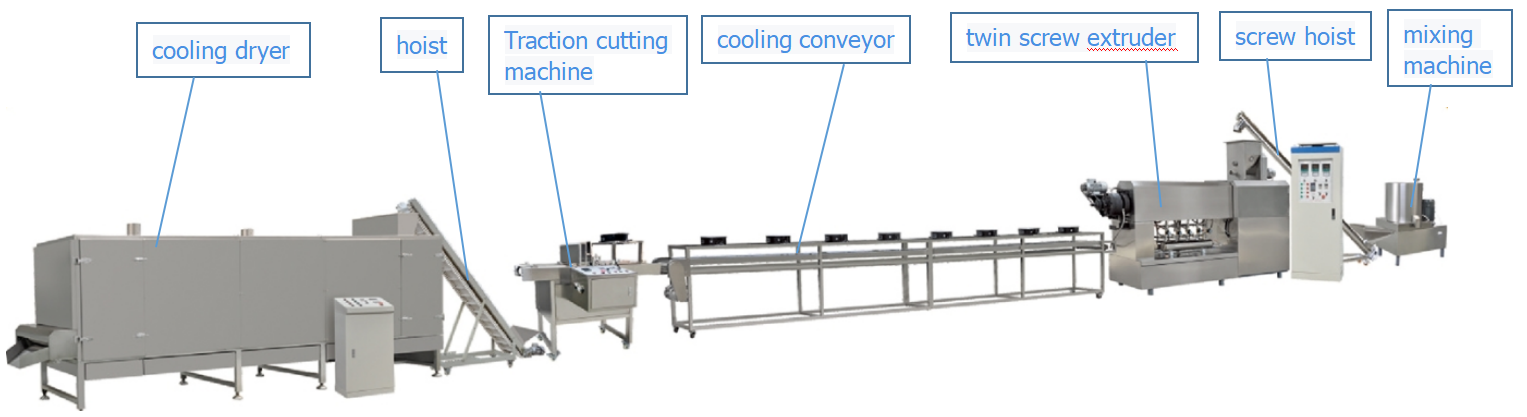

Process flow and equipment composition of edible straw making machine

[1] mixing machine → [2] screw hoist → [3] twin screw host → [4] cooling conveyor → [5] Traction cutting machine → [6] large hoist → [7] cooling dryer

Process description edible straw making machine production line:

1) Raw material preparation: according to the ratio of raw materials, rice, cassava and sweet potato powder stored in the silo (80 cubic meters) are transported to a mixing silo according to the set procedure through three sets of automatic feeding systems, for 8-12 minutes of uniform pre-mixing;

2) Mixing with water: the pre-mixed material is conveyed to the vacuum high-speed mixer through the transmission system, and pure water is added at the same time to fully contact the water, so that the material can be evenly mixed for 5-8 minutes by a certain viscosity;

3) Metering and feeding: the material processed by the vacuum high-speed mixer is transported to the bin with automatic metering and feeding system, and the material is transported to the extrusion equipment through the automatic metering and feeding system;

4) Extrusion process: extrusion equipment temperature control has strict requirements, are controlled by PLC, in accordance with the established temperature production, the material through the extrusion equipment is one is heating material mature, the second is to compress the material volume in order to enter the back of the mold;

5) Mold forming: the material produced by extrusion equipment finally enters a specially designed mold, and the material generates a long strip similar to a straw through the mold;

6) Cooling and drying: the material out of the mold is a hot and soft pipe. After cooling and drying, the primary appearance of the rice straw has been shown;

7) Cutting: after cooling and drying, the product has been fully shaped, and the cutting shall be carried out according to customer's requirements;

8) Packaging: After cutting, the product will enter the straw automatic packaging machine for packing and packing;

9) Inspection: inspect each batch of materials (physical inspection and chemical inspection), as well as the length, diameter, weight, bearing capacity, deformation time of hot and cold water and other physical properties after the finished products come out.

Company after-sales service commitment

1. The company's after-sales service personnel can provide ingredients and basic product formulas for related products.

2. On-site training of relevant personnel of the demanding party on equipment operation and regular maintenance.

3. Regular after-sales telephone return visits to customers to help you solve related difficult problems encountered in the use of the equipment.

4. Our company provides high-quality and low-cost spare parts to the buyer all the year round, and provides equipment upgrades and new product development support, so you really have no worries.

5. If the equipment is damaged due to the expiration of the warranty period, users in the province will arrive at the repair site within two days after receiving the notice from the buyer. Users outside the province negotiate with technical personnel to try to solve the problem as soon as possible.

Packing and transportation

Company Profile:

Jinan Xilang Machinery Co., Ltd. is an extruder, twin-screw extruder, single-screw extruder, breakfast cereal instant food (corn flakes, nutritional powder) production line, leisure (fried, sandwich) snack food production line, pet feed , Fishing bait production line, tissue protein production machinery, modified starch production line, bread crumb production line, experimental twin-screw extruder, reconstituted nutritious rice production line, industrial microwave drying and sterilization equipment, electromagnetic drying tunnel oven and packaging machinery research, development, and production , A manufacturer integrating sales.

The company is located in Jinan, the spring city of Shandong. The company has strong design strength, advanced production equipment and rich manufacturing experience. Through the continuous efforts of our company in the past eight years, it has a group of high-quality engineering design and food technology talents, and dedication to good extruding technology results. To you, high efficiency, high quality and high performance constitute our core competition.

Jinan Xilang Machinery Company warmly welcomes users from all walks of life to inquire, visit and negotiate on site! We serve you wholeheartedly