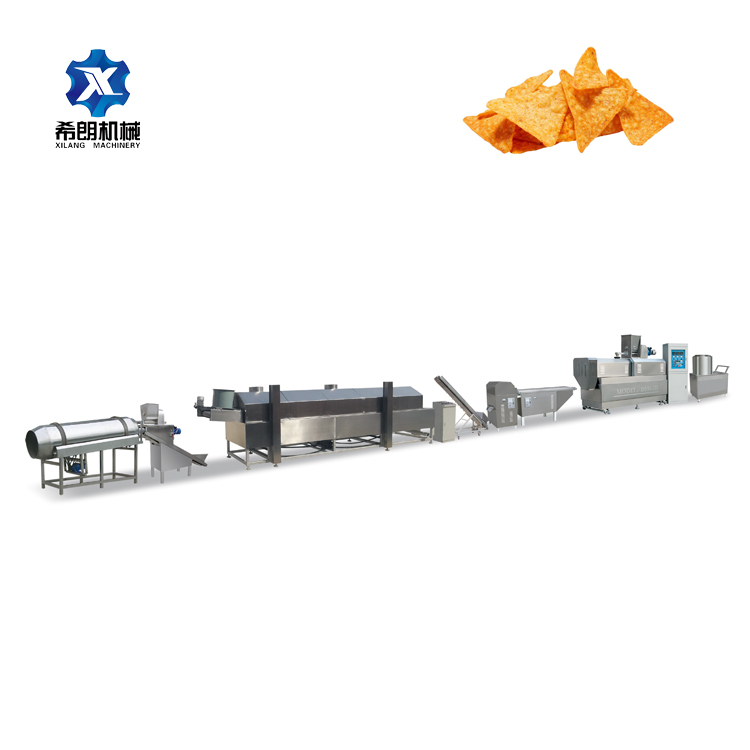

Crispy Fried Corn Bugle Chips Snacks Making Machine

Brand :XI LANG

Product origin :Jinan,China

Delivery time :20days

Supply capacity : 100 sets per month

1.Xilang fried snacks production line is a new technology that replaces the traditional production by twin-screw extrusion technology.The production line including mixing materials, Extruding and expanding, Forming in one, no need boiler, and the production process is simplified, efficient, environmentally friendly and low-carbon.

2.The shape can be changed by changing the mould and the forming machine and the cutting machine, such as strips, waved square sheets, diamond sheets, pillows, and triangles. The Crispy Rice, Salad Chips, and Bugles chips are all varied,and the taste is crisp and not greasy.

3 Bugle snack making machine can produce triangles, gourd shapes, small fish cakes and so on.In addition,it also could process corn by changing cutting machine.

Automatic Corn Bugle Snacks Production Line Making Machine

Brief introduction of bugles chips making machine:

Fried puffed food production line is suitable for flour, corn flour and other raw materials, puffed by twin screw extruder, and then using twin screw extrusion mechanism directly pressed into shape or cut into strip or sheet products, made after frying. It's crispy. After frying, it is deoiled, seasoned and dried to make delicious snacks.

Production line equipment reasonable design, simple operation. Automatic continuous production line and semi-automatic continuous production line can be equipped according to the output and investment needs. By adjusting molds and ingredients, the production line can process fried snacks of various shapes and tastes. Rice cake, small twist, French fries, pizza roll, crispy horn, fish slices, Chicken McNuggets, flower roll, etc.

The technical specification of extruded fried snack making machine

Model | 65 twin screw extruder line | 70 twin screw extruder line |

kw Installed power | 45kw | 55kw |

kw Actual consumption power | 30kw | 35kw |

Production capacity | 120-150kg/h | 180-250kg/h |

Appearance size | 12000x1600x2300 | 13000x1600x2300 |

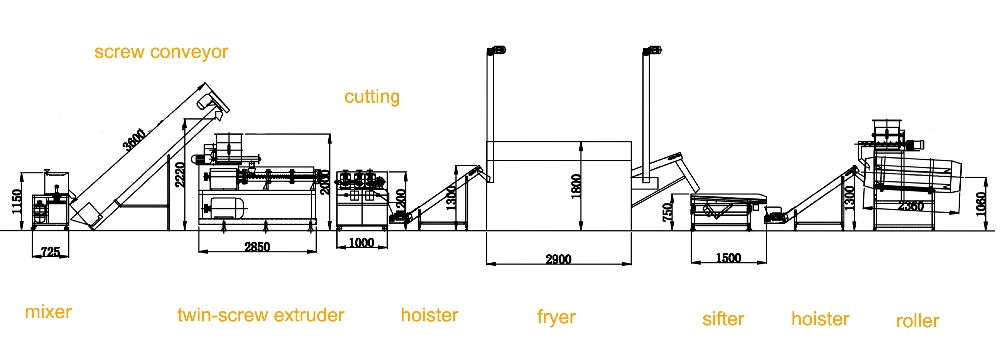

Process flow of small twist production line equipment:

Raw material preparation → powder mixing → puffing machine → lifting → automatic frying → seasoning → packaging

The components of bugles chip production line equipment:

1. Flour mixer: mix the main ingredients (corn flour, rice flour, etc.) alone or add additives, and mix a certain amount of water to mix well.

2. Puffing machine: through extruding and puffing to produce long slices of rice crackers, changing the mold can be used for rice crackers with different widths and thicknesses.

3. Shaping and cutting machine: cutting and printing the long strip semi-finished products from the extruder.

4. Automatic fryer: deep frying

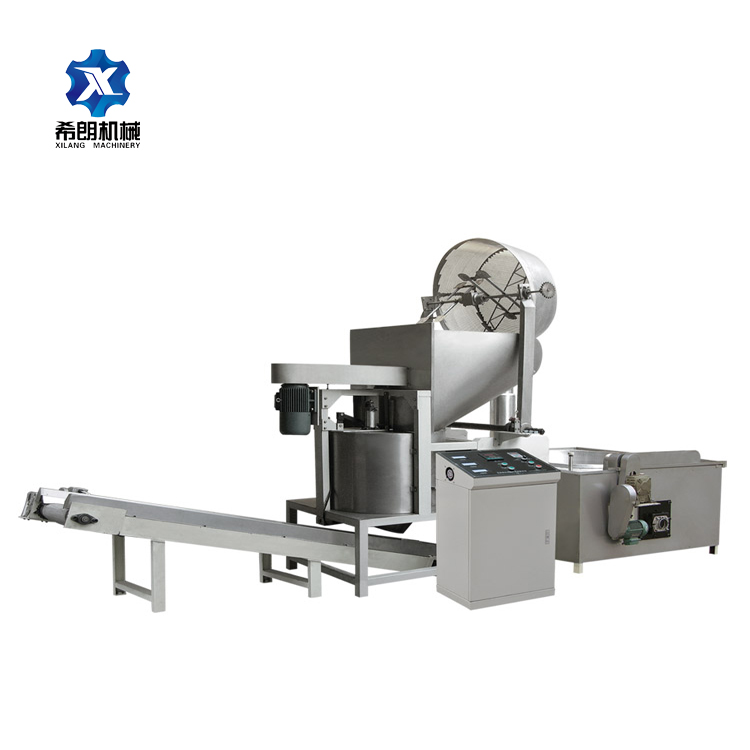

5. Seasoning line: There are octagonal tube, cylinder, lifting single drum, double drum seasoning line, after frying, spray the flavor material in the tube.

6. Packaging machine: vertical packaging machine or combined computer cool packaging machine, which can optionally pack different bags.

Sample pictures

Services

The company's technical department continues to develop and innovate according to market needs, and at the same time, it has never stopped improving and upgrading equipment according to customer requirements.

The company's sales department is divided into domestic business department and business department, which can better provide more professional sales guidance for domestic and customers

Acceptance of equipment and spare parts. Full-time quality control personnel conduct batch inspections on outsourcing and outsourcing parts. Quality inspections for key and precise spare parts are carried out.

Company profile

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

FAQ

1 Are you manufacturer or trading company?

We are the manufactuer,welcome to visit us.

2 Whether you could make your brand on the products?

Yes, we could print your logo on both products and packages.

3 How about the guarantee period?

The guarantee period is 1 year after machine leave our company

4 What is the terms of payment?

30% T/T in advance, the balance before goods leave our company.

5 How long is the delivery time?