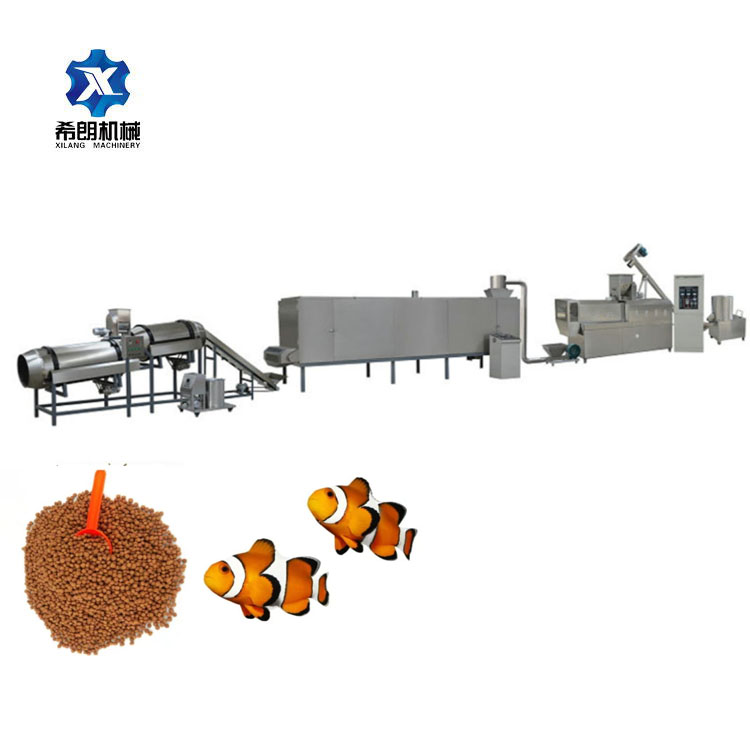

Floating fish feed pellet extruder making machine

Brand :Xilang

Product origin :Jinan China

Delivery time :20days

Supply capacity :100sets/month

1.Can produce floating feed, slow sinking feed, sinking feed.Small investment, high output, small area space.

2.The whole machine of small and medium-sized fish feed production line is made of stainless steel. It Can be widely used in the production of fish, shrimp, crab, abalone, sea cucumber and various ornamental fish feed.

3.The production line adopts internationally advanced twin-screw extrusion technology. can accurately control the increase of the density of the product.The puffing machine can choose dry puffing and wet puffing.

1.Product Description

Brief Introduction of fish feed pellet making machine

The fish feed floating pellet making machine is suitable for fish food at different growth stages. Changing molds to make fish food of different shapes.In addition,it also could produce dog food, cat food, fox food, rabbit food and so on.

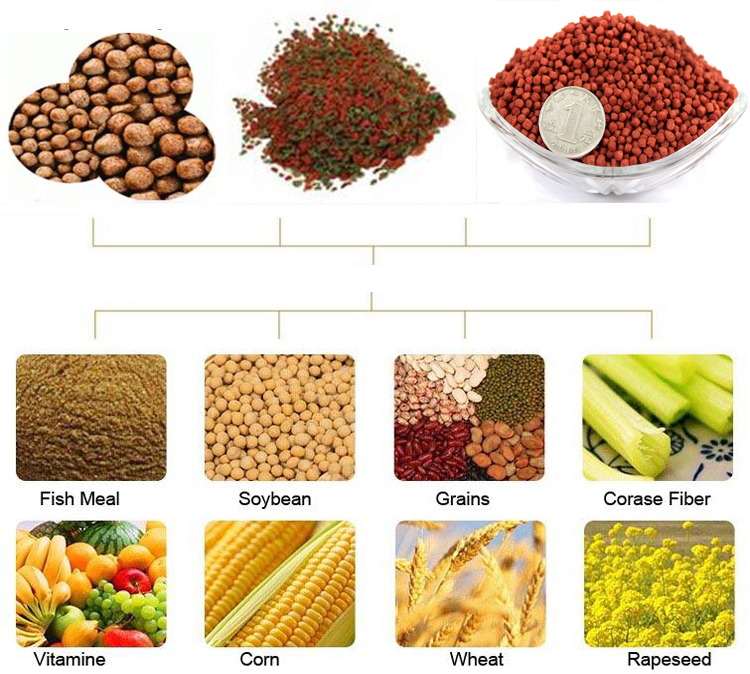

Raw materials of fish feed production machine

adopts corn flour, fish meal as raw materials

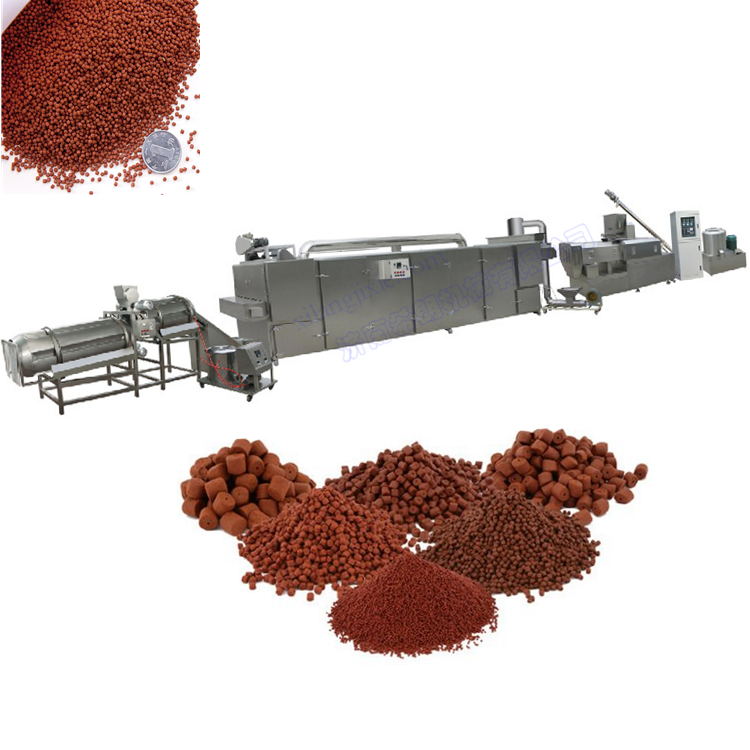

Products which could be produced by fish feed production machine

fish feed process line can be used to produce fish pellets, the pellets size can be from 0.6mm to 9.0mm by adjusting the moulds from extruder; meanwhile it can produce dog food, cat food and so on.

2.Specification of fish feed pellet making machine extruder processing line

Model | XL65 | XL70 | XL85 | XL95 |

Total installed power | 100-120KW | 130-180KW | 190-200KW | 300-450KW |

Actual consumption power | 70-90KW | 90-110KW | 110-130KW | 190-210KW |

Production capacity | 100-150kg/h | 200-260kg/h | 300-550kg/h | 800-1200kg/h |

Size | 12x1.2x2.3m | 18×1.3×2.4m | 20×1.3×3.4m | 45×4.5×3.4m |

Plant area occupation | 40-50 m² | 50-60 m² | 90-120 m² | 150-200 m² |

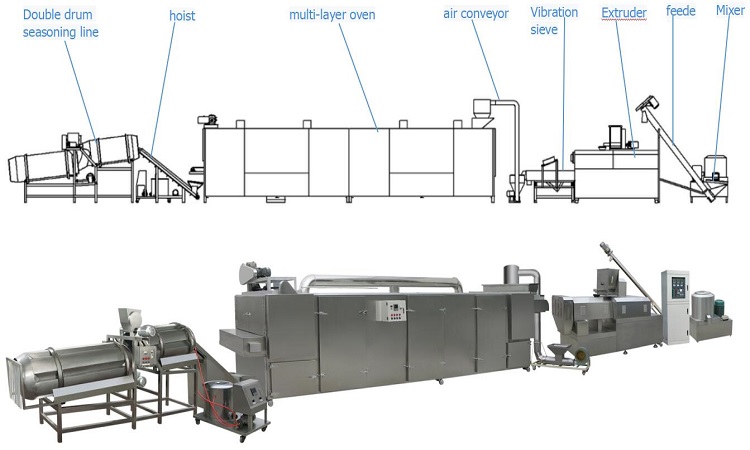

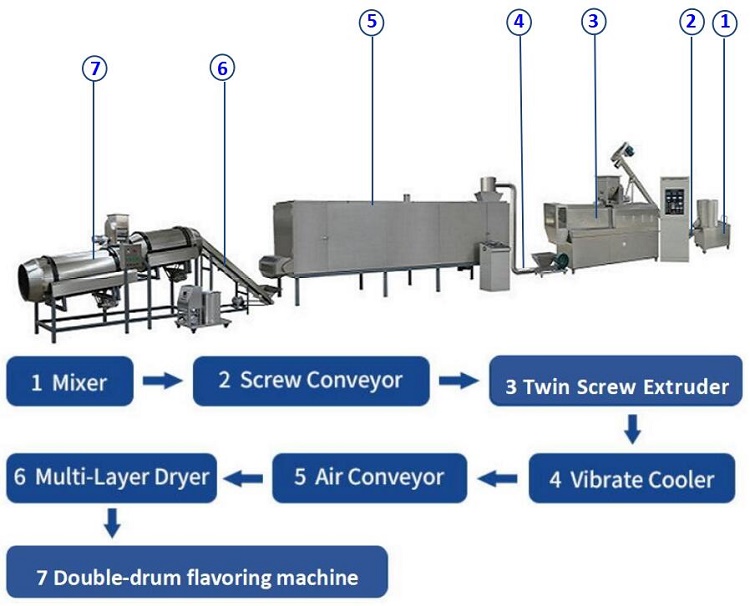

3.Flow chart of fish feed pellet making machine extruder processing line

Equipments list of fish feed pellet making machine extruder processing line:

mixer --- screw feeder --- twin screw extruder --- air conveyor --- dryer --- double-drum flavoring machine-- - cooling conveyor

NO. | Machine Name | Function |

1 | Mixer | Mix the raw material and other additives fully. |

2 | Screw conveyor | Screw conveyor transfer the raw material in the sealed tube,no leaking and no pollution |

3 | Twin screw Extruder | The material is fully matured under high temperature and pressure, through the outlet mold expansion, form foods of various shapes. |

4 | Air Conveyor | conveys the food relying on the wind-force from the blower |

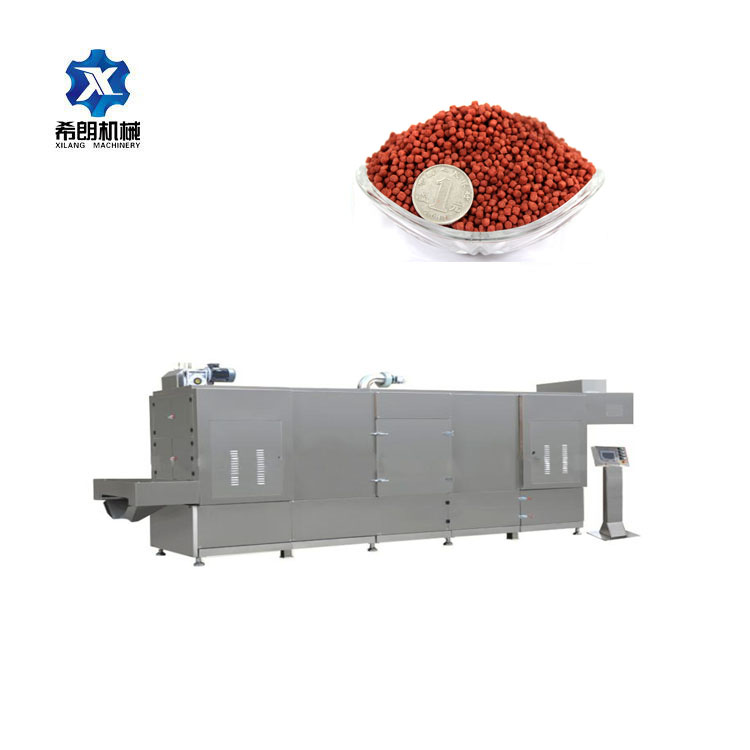

5 | Muti-layer Dryer | Used to bake and dry food, Net belt running speed can be controlled |

6 | Hoist | Convey the products into flavoring machine |

7 | Double rolls flavoring line | The stainless steel flavor feeder is used to spray flavor to the drum |

Detail Machines Pictures:

4.Sample Photos of fish feed pellets

5.Extruder Features

Pure copper motor, low heat, sufficient power and stable performance

The control cabinet adopts a visual automatic temperature control system, the temperature of each zone can be adjusted separately, the temperature control is intuitive, and the parameters are accurate

Double screw in the same direction, controlled by a separate control cabinet

The screw is made of high wear-resistant materials with hardness above HRC55 and has a long service life

International brand power supply devices, strong stability, can run continuously for more than 700 hours

6.Packing and Shipping

Packing Detail:

1.Inner packing: Stretch film

2.Outside packing: Standard export wooden cases

3. The package also can be according to customer requirements.

7.Company Profile

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

8.FAQ

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q: What is your terms of payment ?

A: 30% T/T in advance ,70% balance before shippment after inspection.

Q: How about the after-service?

A: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators.