floating fish feed processing machine line

Brand :Xilang

Product origin :Jinan

Delivery time :15days

Supply capacity :29 units per month

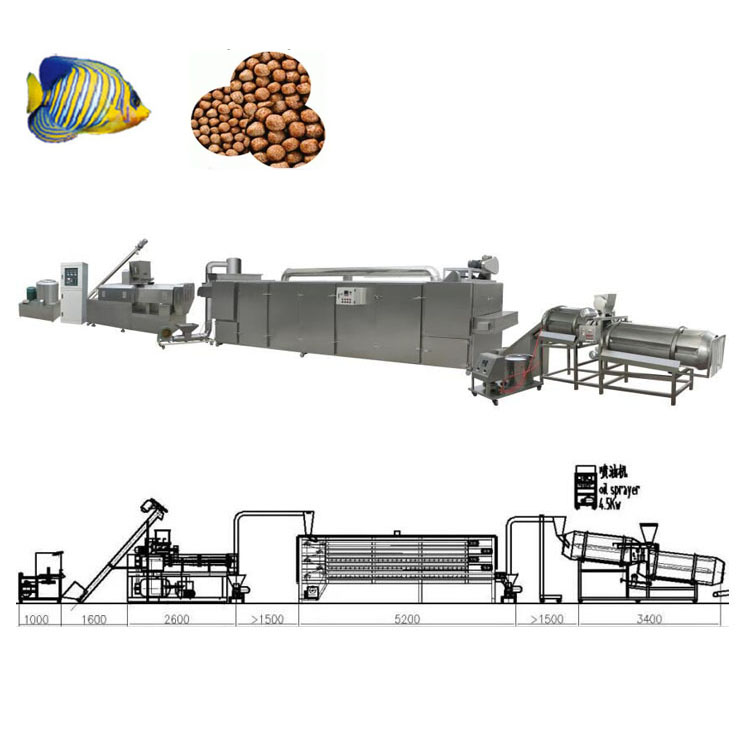

1.The floating fish feed processing machine line can make kinds of feed for different fish, such as fish, catfish, shrimps, crab, etc.

2.Extruder for fish feed production process is deliberately made for special feed, which needs high in-shape rate and good-looking appearance.

3.High Efficiency,the floating fish feed processing machine line Low electricity and labor consumption,

1.Brief introduction of floating fish feed processing machine line

The floating fish feed processing machine line can be used to produce fish pellets, the pellets size can be from 0.6mm to 9.0mm by adjusting the moulds from extruder; meanwhile it can produce dog food, cat food and so on.

2.The technical specification of floating fish feed processing machine line

XL65 -III | XL70 -II | XL70 -IV | XL75 -III | XL95 -III | |

Type | dry | dry | wet | wet | wet |

Main power Consumption/Installed | 22KW/30KW | 30KW/40KW | 37KW/45KW | 55KW/75KW | 90KW/110KW |

Capacity | 120-150kg/h | 150-180kg/h | 300-400kg/h | 600-800kg/h | 1000-1200kg/h |

Size(m) | 12x4x2.2m | 13.5x4x2.2m | 16.5x4x3.2m | 18.5x4x3.2m | 21x4x3.2m |

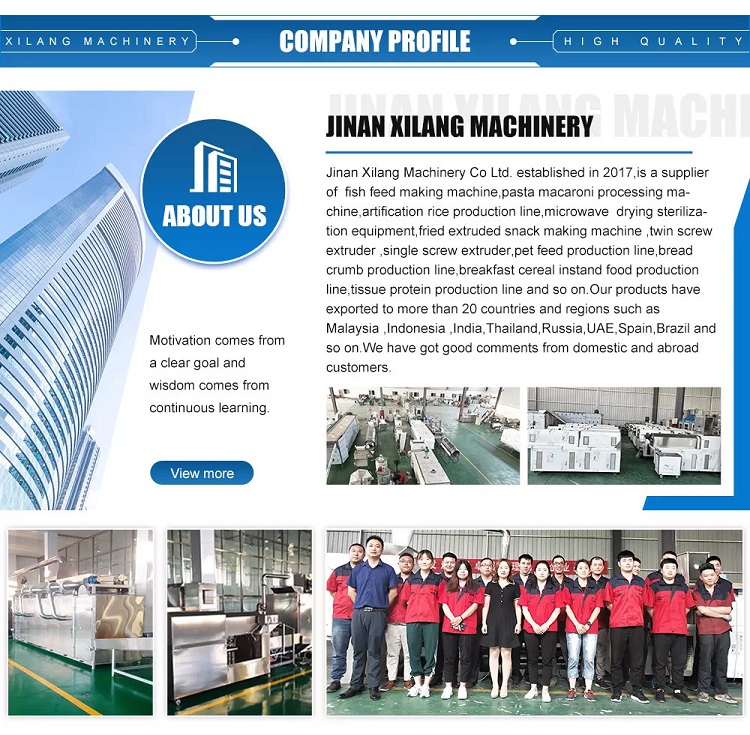

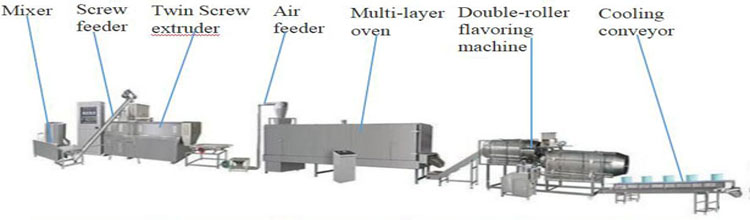

3.The flow chart of floating fish feed processing machine line

Raw material---Mixing---Screw Conveying---Extruding---Air Conveying---Drying---Air Conveying---Flavoring---Cooling

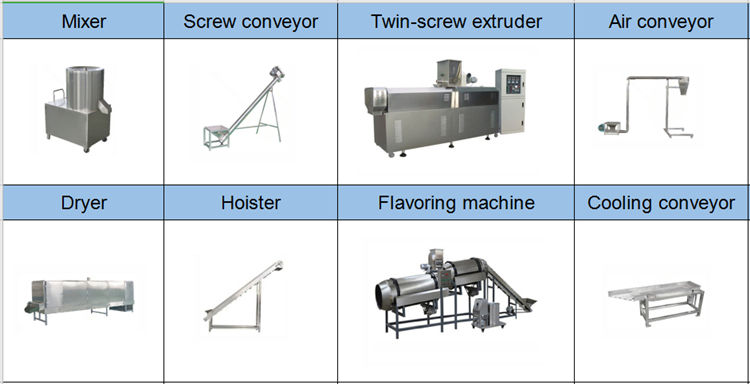

4.The equipments list of floating fish feed processing machine line

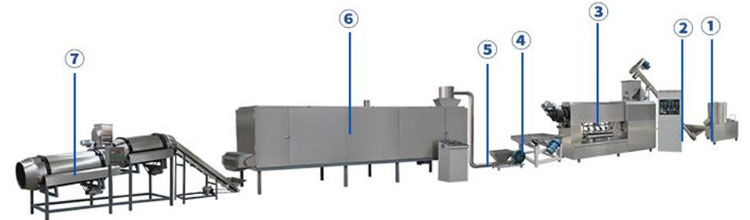

5.The composition of floating fish feed processing machine line

NO. | Machine Name | Function |

1 | Mixer | Mix the raw material and other additives fully. |

2 | Screw conveyor | Screw turns to make the raw material convey in the sealed tube,no leaking and no pollution |

3 | Twin screw Extruder | The material is fully matured under high temperature and pressure, through the outlet mold expansion, form foods of various shapes. |

4 | Air Conveyor | conveys the food relying on the wind-force from the blower |

5 | Muti-layer Dryer | Used to bake and dry food, Net belt running speed can be controlled |

6 | Hoist | Convey the products into flavoring machine |

7 | Double rolls flavoring line | The stainless steel flavor feeder is used to spray flavor to the drum |

6.Main machine features

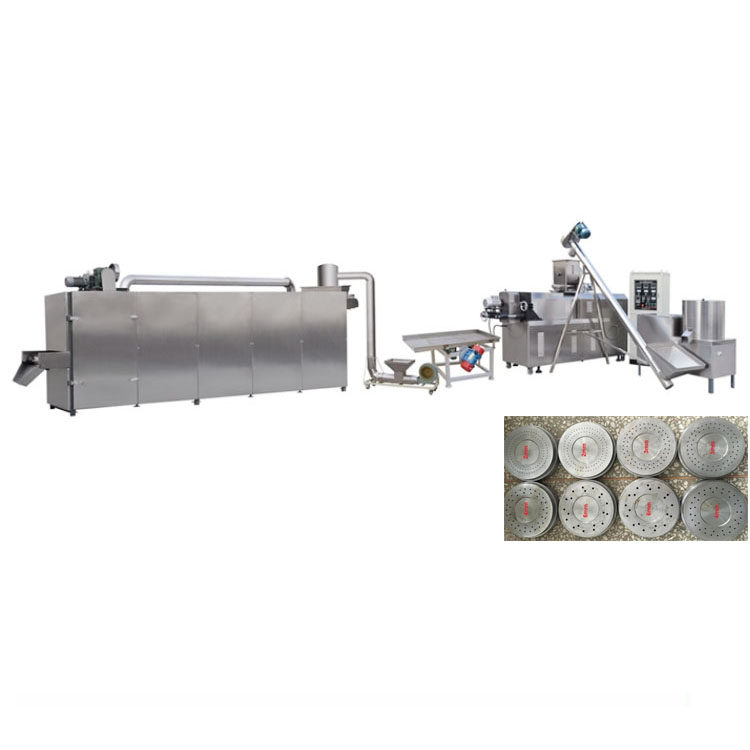

Twin Screw Extruder

1)Pure copper motor, low heat, sufficient power and stable performance

2)The control cabinet adopts a visual automatic temperature control system, the temperature of each zone can be adjusted separately, the temperature control is intuitive, and the parameters are accurate

3)Double spiral in the same direction, controlled by a separate control cabinet

4)The screw is made of high wear-resistant materials with hardness above HRC55 and has a long service life

5)International brand power supply devices, strong stability, can run continuously for more than 700 hours

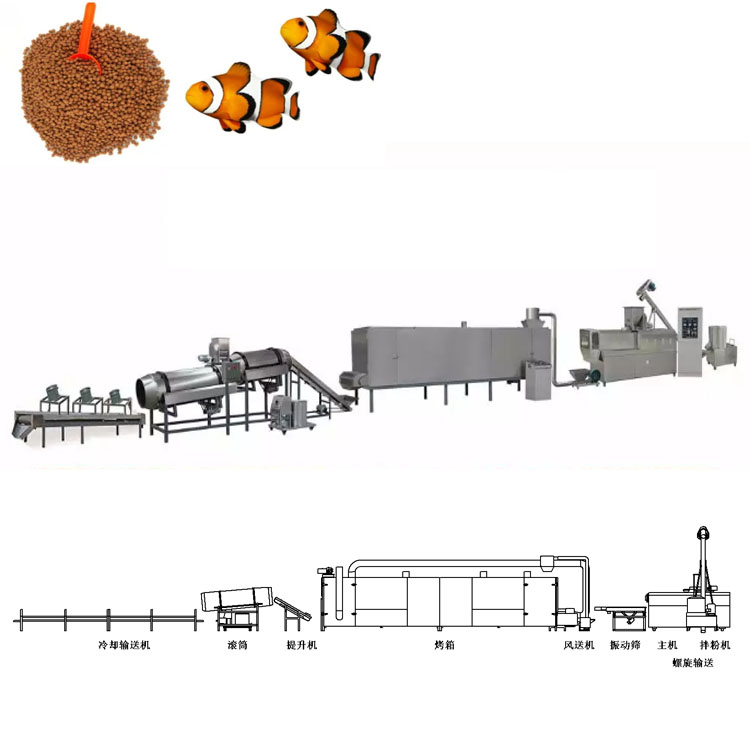

Muti-layer dryer

1)Five-Layers Roaster is used to dry a wide range of products, such as macaroni,dog snacks, corn flakes, core filling food, etc.

2)Five layer structure can prolong the drying time and reduce the coverage area;

3)Each layer is made of mesh belt with stainless steel;

4)Side guard to prevent products falling from the belt;

5)Various speed inverter drives for five layers;

6)Auto temperature control system with the temperature range between 15-180℃;

7) The body is well sealed to prevent any heating leakage, and thus reduce the savings in energy;

8)Equipped with special thermal-protective coating to prevent any burnt or scald to the workers;

9)Adjustable door hinge; flat laying mesh belt; tailor-made materials receiver Three kinds of power available: Electric, gas or oil.

7.Packing and Shipping

Packaging: daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film. Finally pack them with wooden case.

transportation cost:

by ship-please tell me your delivery port; by air-please tell me your airport name; by express-please tell me your detailed address(including zip code, house number, street, city, country).

8.Certificates and Projects

9.Company Profile