Fried Wheat Flour Snacks Production Line

Brand :XI LANG

Product origin :Jinan,China

Delivery time :20days

Supply capacity : 100 sets per month

Fried Wheat Flour Snacks Production Line

1. The production line takes wheat flour as the main raw material to fry and flavor the fried leisure food of various shapes and flavors. Twin-screw extruder products can be fried directly without drying.

The production line is reasonable in design, easy to operate and easy to understand. It is suitable for processing popular products such as shrimp slices and crab strips.

3. Fried flour snack line use double screw extruder technology

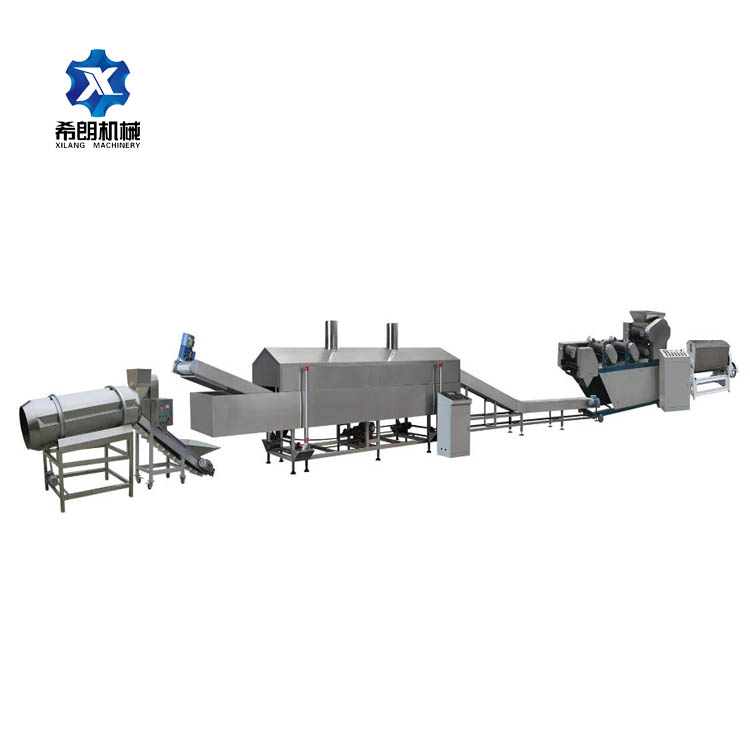

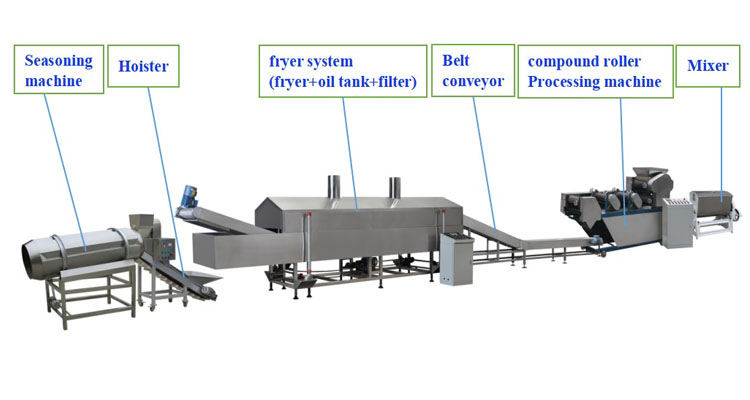

Fried Wheat Flour Snacks Production Line Making Machine

Brief Introduction of fried flour snack making machine:

The frying flour extrusion production line is suitable for mixing flour and other raw materials, pressing by a number of rollers, using special cutting mechanism to cut the products into different shapes, and then puffing after frying. After frying, seasoning is added to make delicious snacks.

The technical specification of fried flour puffing production line

Model | Fried flour production line (electric ) | Fried flour production line ( oil,gas) |

Installed power | 60kw | 12L/H oil /8-12m³ gas |

Actual consumption power | 40-50kw | 3kw |

Production capacity | 150-200kg/h | 150-200kg/h |

Appearance size | 12*0.8*1.5m | 12*0.8*1.5m |

Process flow of fried flour snack processing machine:

Kneading machine - compound roller pressing machine - cutting machine - conveyor - frying machine - vibration deoiling machine

- single drum flavoring machine - cooling machine

Introduction to the main components of the puffed snack production line:

Powder mixing machine: Mix the powdered raw materials according to the formula ratio, and select a suitable powder mixing machine according to the production line output and the viscosity properties of the raw materials.

Feeding machine: The motor is used for screw conveying, and the mixed raw materials are conveyed to the feeding hopper with a certain height of the extruder to ensure convenient and fast feeding.

Twin-screw extruder: Choose different types of extruder according to the output of the production line, the output can range from 100kg/h to 1000kg/h, and different types of extruders can be selected according to the products made

Cutting machine: cutting of frying products, bar and sheet products, baking products, barley and rice crackers

Sandwiching machine: Fill the rice crackers with the filling, you can add chocolate, butter, egg yolk, peanut butter, jam, etc.

Cooling elevator conveying: automatic conveying of various equipment products, according to the needs of different extruded products, there are choices of PVC conveyor belts, stainless steel conveyor belts, and customized processing according to output and plant restrictions

Multi-layer oven: non-fried puffed food is baked to make the product more crispy, tasty, and increase the taste. At the same time, the moisture of the material is dried to increase the shelf life. Ovens can be divided into climbing ovens and ordinary ovens according to the configuration requirements of the production line. According to the energy mode, electric heating, natural gas heating, and steam heating can be selected. According to the drying temperature, high-temperature drying box and low-temperature drying box can be selected, and circulation structure and constant current structure can be selected according to the internal structure. The temperature is adjusted between 0-200 degrees through the control cabinet, the internal part in contact with the puffed food is made of stainless steel, and the baking time can be adjusted according to the speed

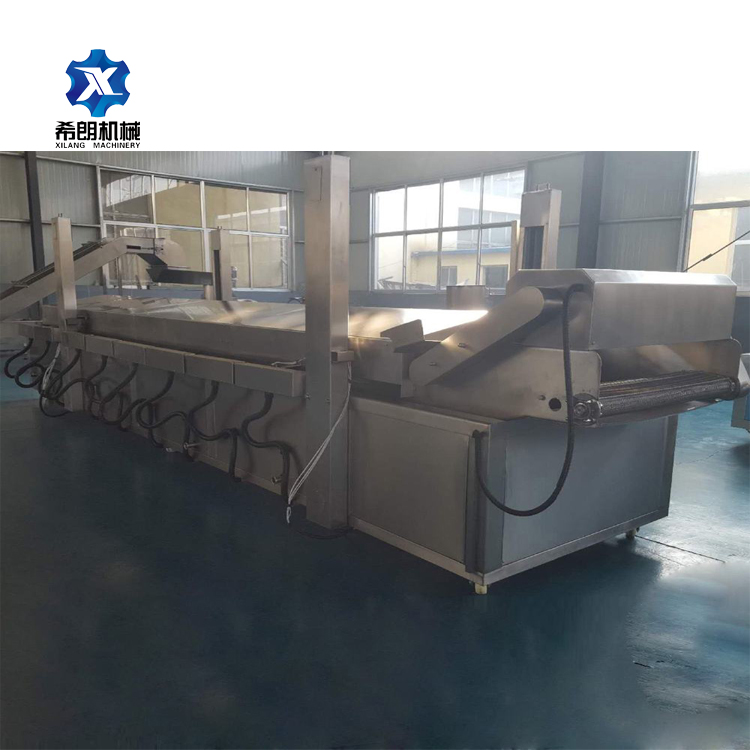

Fryer: Deep-fried puffed foods need to have better product shaping properties when they are puffed, and have a large water content. After being formed by the puffing machine, they will directly enter the frying machine for frying and dehydration to make the product crisp. Xilang company's fryer has semi-automatic fryer, tunnel type, continuous fryer, and double-layer belt tunnel fryer (special for floating puffed food before sinking). There are single-cylinder de-oiling machine and double-cylinder de-oiling machine. Meet the needs of semi-automatic and automated continuous production.

Seasoning line: There are octagonal tube, single drum, double drum seasoning lines, which are configured according to the output and the nature of the product. There are also oil spraying, sugar spraying and coating equipment. In order to meet the needs of market development, Jinan Xilang Machinery Co., Ltd. has developed batch weighing and seasoning mixing equipment, single-head octagonal seasoning machine, double-headed octagonal seasoning machine, and forward and reverse seasoning machine. Improve the product mixing uniformity and accurate control of the added amount of seasonings.

Features of fried flour production line:

(1) The equipment is made of stainless steel, which is hygienic, safe and reliable.

(2) No boiler is needed, which eliminates the danger of high-pressure boiler.

(3) There is no pollution and noise, and no pollution to the environment.

(4) The equipment is integrated with the assembly line, the appearance is beautiful and generous, and the floor space is small.

(5) The equipment is easy to operate and has a high degree of automation, which saves time and effort, and reduces labor consumption.

(6) Patented heat conversion heating, which saves more production costs.

Sample Pictures

Packaging and delivery:

1.Packaging: All fried flour snack making machines are packaged according to international standard export package.Inside is covered by plastic film, outside is wooden case.

Our Services

a. ) Consultation service before, during, and after sales;

b .) Project planning and design service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

f.) Provide 1 year complete warranty and life-time maintenance service.

Company Profile:

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

FAQ

1. What's the pre-sale service of your company for fried flour snack making machine ?

Related machines’s technical parameter will be supplied to customer.

1.1 Layout can be provided in advance basing on customer’s factory size.

1.2 General formulation can be offered according to customer’s material cost,.

1.3 Machine could be customization.

1.4 Professional suggestion for Market, machines, processing , materials, packing.

1.5 Suggesting professional ship agent or helping book ship according to customer situation.

2. What's the after-sale service of your company for fried flour snack making machine ?

2.1. Allocation chart will be offered as the buyer’s request .

2.2. Professional Operation manual will be supplied after shipment.

2.3. One year warranty support, life time maintenance with cost price.

2.4. Free easy broken spare parts will be sent together with machines .

2.5. First installation supports.

2.6. Worker training supports.

3. what about spare parts after sale service for fried flour snack making machine?

We can offer the wearing parts all the time together with changing video.

We are the manufactuer,welcome to visit us.

Yes, we could print your logo on both products and packages.