Automatic Puffed Fried Bugles Snack Making Machine

Brand :XI LANG

Product origin :Jinan,China

Delivery time :20days

Supply capacity : 100 sets per month

1 Bugles extruder machine use corn flour, wheat flour and other grains as raw material to produce extruded snacks.

2 Different shapes can be made by adjusting the dies from extruder

3 The screw material of bugles making machine is 38CrMoAl.It has high strength and wear-resting.

4.After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

5.Guarantee time is 2 year.

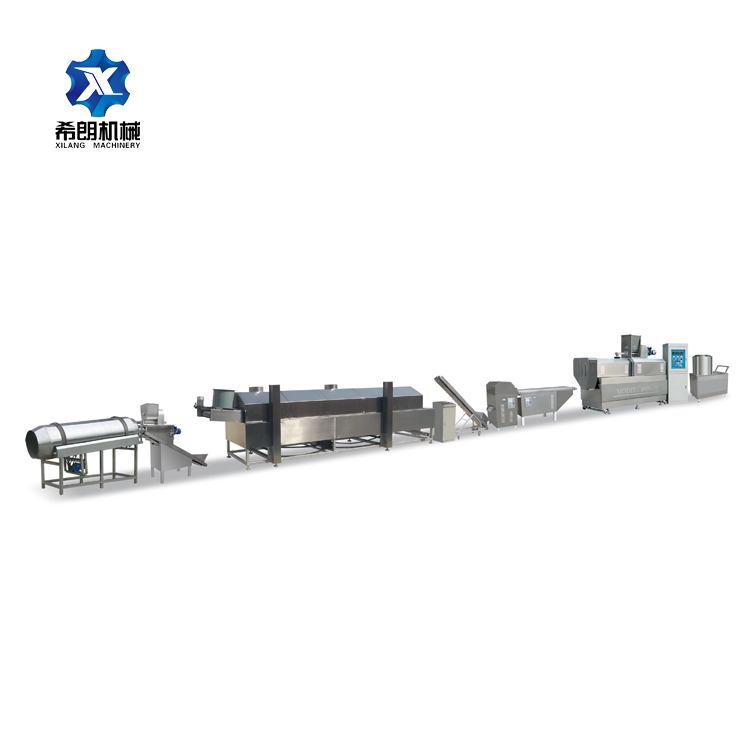

Fried Corn Bugles Extruder Machine Production Line

Brief introduction of bugles production line:

Fried puffed food production line is to use a double-screw extruder blowing steam flour, corn and other raw materials, using a special mechanism pressure molding or directly cut into pieces of products, made after frying.The taste is very crisp.Deep fried, seasoned and dried for a delicious snack.

The technical specification of extruded fried snack making machine

Model | 65 twin screw extruder line | 70 twin screw extruder line |

kw Installed power | 45kw | 55kw |

kw Actual consumption power | 30kw | 35kw |

Production capacity | 120-150kg/h | 180-250kg/h |

Appearance size | 12000x1600x2300 | 13000x1600x2300 |

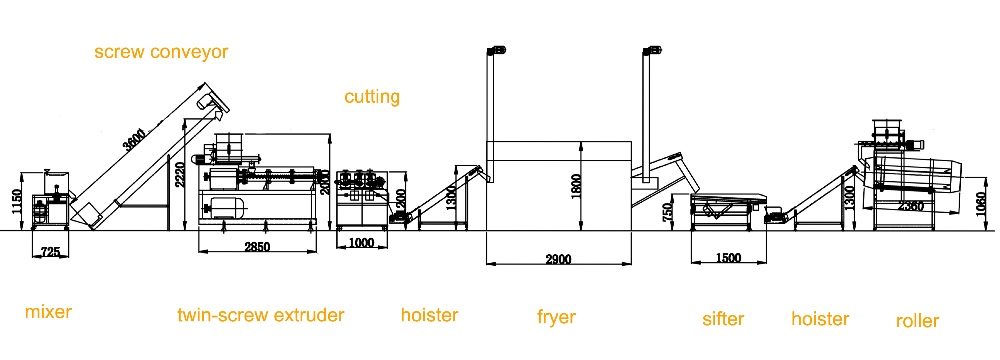

The flow chart of bugles production line:

Raw material mixing → extrusion puffing → shaping and cutting → frying → spraying seasoning → cooling → packaging

Device Configuration:

1) Powder mixer → 2) Screw feeder → 3) Twin screw extruder → 4) Shaping and cutting machine → 5) Lifting machine

→ 6) Frying pan → 7) Oil slinger → 8) Drum seasoning line → 9) Cooler → 10) Packaging machine

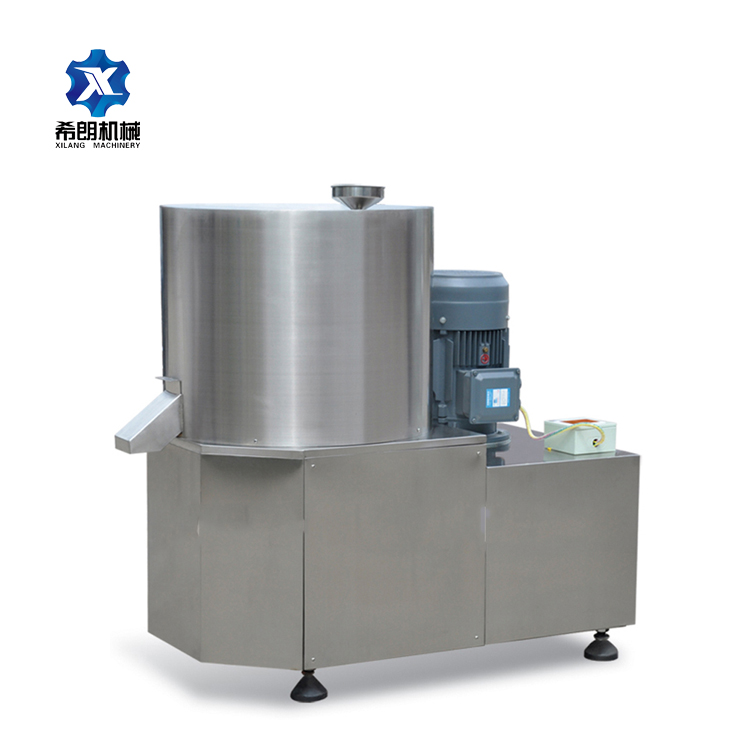

Introduction of frying system:

The semi-auto fryer is composed of a pot body, a shell, a heating tube, an electric control box, a motor, a frying basket, an oil drain valve, a stirrer, etc.

1.Operation process: set the frying temperature and the oil temperature rises to the required temperature. After frying and frying, press the pan button, the frying basket will automatically lift, pour the fried food out, and then press the pan button , Fry the basket back to the pot, continue to pour the food in for frying.

2.Adopt intelligent digital display thermostat, automatic temperature control is equipped with over-temperature protection device.

3.The frying basket is equipped with high-quality stainless steel punching, and the automatic unloading can better separate the material and the oil. The wide arc shape along the discharge port of the basket can ensure that all materials are discharged into the next process when the material is discharged.

4.The electric appliance is controlled uniformly, and the frying time and frying temperature are uniformly set.

5The blowdown valve adopts a large diameter, which is not easy to be blocked. The mixing can be disassembled.

The twin screw extruder can also produce rice cakes, small twist, French fries, pizza rolls, crispy Angle, fish chips, McNuggets, small roll and other products.

Sample picture

Xilang service Commitment:

1. Equipment design and production of fried puffed food production line. Our company is undertaking equipment processing design and production stage, soliciting opinions from the demand side, especially in the layout of the flat facade, fully considering the demand side's site conditions and public engineering conditions, so that While ensuring the quality of the equipment, it also takes into account the optimized combination.

2. Installation and debugging When the equipment arrives in the buyer's factory, our company will send a full-time technician to the buyer to guide the installation and be responsible for debugging to normal use.

3. Quality Assurance The warranty period of our company's equipment is one year. During the warranty period, the equipment is damaged by non-human factors, and is responsible for free maintenance. If the equipment is damaged by human factors, our company will repair it in time and charge a cost fee.

4. Repairs and equipment damage due to the expiration of the warranty period, after receiving the notice from the buyer, the enterprises in the province will arrive at the site for maintenance within two days, and the enterprises outside the province will arrive at the site within four days. The services provided by the warranty period are paid services, each service Costs are charged.

5. Spare parts supply Our company provides the purchaser with high-quality and favorable price spare parts and related supporting services for many years.

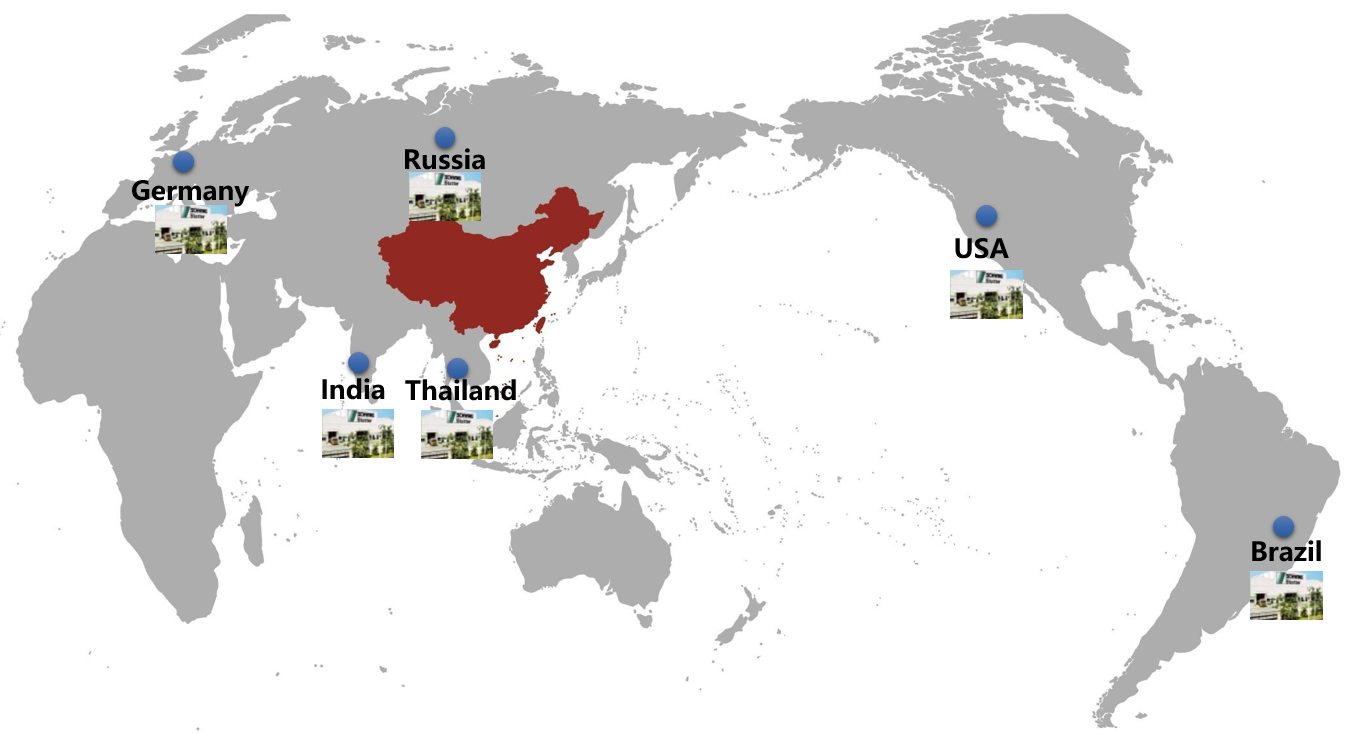

Sales and services network

Company profiles

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.