ornamental fish feed machine extruder

Brand :Xilang

Product origin :Jinan

Delivery time :15days

Supply capacity :30uints per month

1.The ornamental fish feed machine line adopts international advanced twin-screw extrusion technology, with small investment, high output and small occupation area.

2.The fish feed manufacturing machine extruder is suitable for different growth stages of fish food. Change molds to make different shapes of fish food.

3.Adjust the raw material, temperature, moisture and other technological parameters, so that the product has the characteristics of novel shape, unique texture, rich nutrition, delicate organization etc.

1.Brief introduction of ornamental fish feed machine extruder

The ornamental fish feed production line can be widely used in the production feed of fish , shrimp, crabs, abalone, sea cucumbers and various ornamental fish .Changing molds to make fish food of different shapes.

In addition,it also could produce dog food, cat food, fox food, rabbit food and so on.

2.The technical specification of ornamental fish feed machine extruder

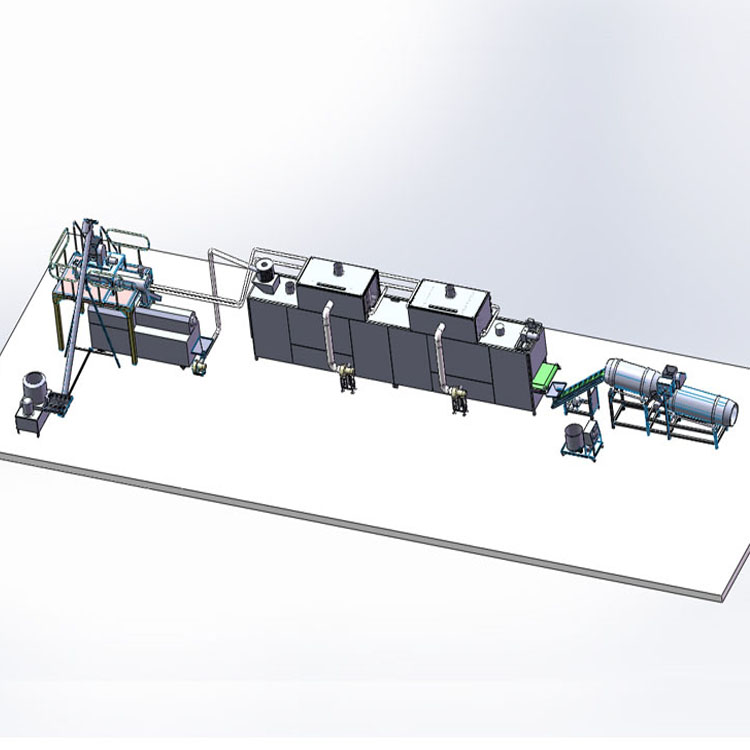

Model | XL65 -III | XL70 -II | XL70 -IV | XL75 -III | XL95 -III |

Type | dry | dry | wet | wet | wet |

Main power Consumption/Installed | 22KW/30KW | 30KW/40KW | 37KW/45KW | 55KW/75KW | 90KW/110KW |

Capacity | 120-150kg/h | 150-180kg/h | 300-400kg/h | 600-800kg/h | 1000-1200kg/h |

Size(m) | 12x4x2.2m | 13.5x4x2.2m | 16.5x4x3.2m | 18.5x4x3.2m | 21x4x3.2m |

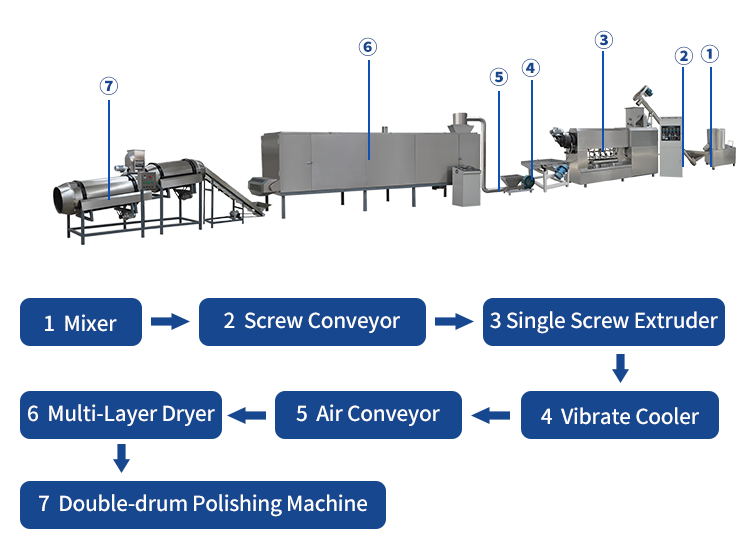

3.Flow chart of ornamental fish feed machine extruder

Raw material Mixing---Extruding---Drying---Flavoring---Cooling

4.Equipments list of ornamental fish feed machine extruder

mixer --- screw feeder --- twin screw extruder --- air conveyor ---muti-layer dryer /oven --- air conveyor --- oil sprayer --- double-roller flavoring machine --- cooling conveyor

NO. | Machine Name | Function |

1 | Mixer | Mix the raw material and other additives fully. |

2 | Screw conveyor | Screw turns to make the raw material convey in the sealed tube,no leaking and no pollution |

3 | Twin screw Extruder | The material is fully matured under high temperature and pressure, through the outlet mold expansion, form foods of various shapes. |

4 | Air Conveyor | conveys the food relying on the wind-force from the blower |

5 | Muti-layer Dryer | Used to bake and dry food, Net belt running speed can be controlled |

6 | Hoist | Convey the products into flavoring machine |

7 | Double rolls flavoring line | The stainless steel flavor feeder is used to spray flavor to the drum |

5.Main machine details of ornamental fish feed production line

Name | grinder | | |

Usage | corn,sorghum,wheat,beans, cottonseed meal,canola,etc. It can do coarse grinding and fine grinding processes | ||

Type | Hammer Mill | ||

Motor | 7.5kw, 15kw, 22kw, 55kw, 75kw and so on | ||

Capacity | 100kg/h to 10 ton/h | ||

| Name | Mixer | |

Usage | To mix the raw materials evenly, fast speed, no leakage. | ||

Type | including Single axle and double shaft mixer | ||

Motor | 3kw, 4kw, 7.5kw etc. | ||

Capacity | 20kg/time, 50kg/time, 100kg/time, 200kg/time, 500kg/time etc. | ||

Name | Screw Conveyor |  | |

Usage | The mixed materials can be conveyed in the stainless steel roller to the feeding machine without any leaking&dusting. | ||

Motor | 3kw, 4kw, 7.5kw etc. | ||

Capacity | 20kg/time, 50kg/time, 100kg/time, 200kg/time, 500kg/time etc. | ||

Material | stainless steel, carbon steel | ||

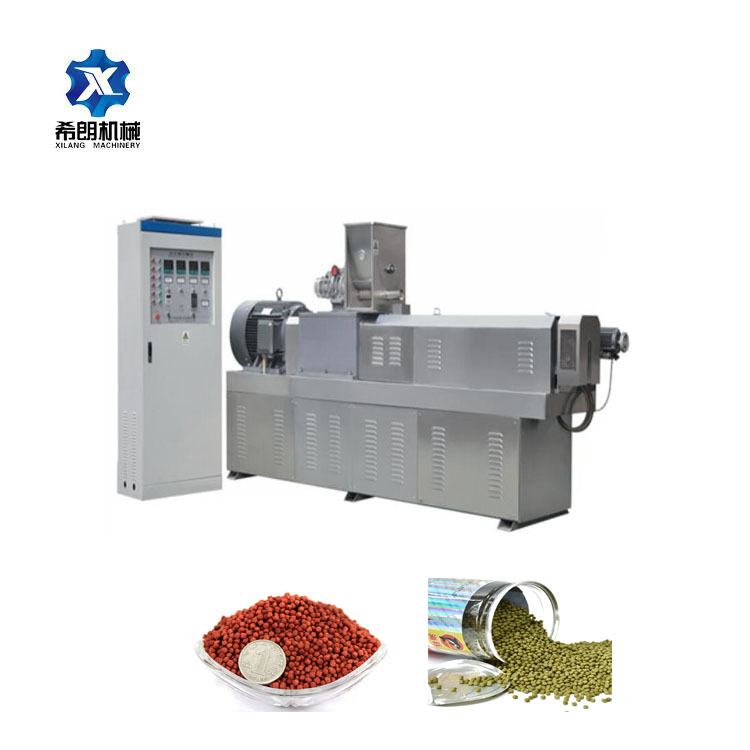

| Name | Twin screw extruder (wet type/dry type) | |

Usage | To extrude the raw materials and make them to the required shape and size of the fish feed pellets by mould | ||

model | XL 65, 70, 75, 90, 95, 100 | ||

Motor | 22kw, 30kw, 55kw, 75kw, 90kw, 110kw etc. | ||

Capacity | 100kg/h to 1500kg/h | ||

Material | Screw materials 38CrMoAl | ||

Name | Dryer |  | |

Usage | the expanded food go through the “s” passage, to be dried to increase the self life. | ||

Heating method | electricity, steam, gas, diesel | ||

Motor | KX-3-5, KX-5-5, KX-5-8, KX-5-10etc. | ||

Capacity | 100kg/h to 10 ton/h | ||

| Name | Flavoring machine | |

Usage | To mix the oil and flavors on the surface of the fish feed | ||

Type | single and double flavoring drum | ||

Motor | 0.75kw | ||

Capacity | 100kg/h to 10 ton/h | ||

Material | stainless steel | ||

6.Sample photos of ornamental fish feed products

7.Packing and Shipping

Packaging:

1)daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film. Finally pack them with wooden case.

2)Customer's requirement is available.

Shipping:If you want to know the transportation cost:

by air-please tell me your airport name;

by express-please tell me your detailed address(including zip code, house number, street, city, country);

by ship-please tell me your delivery port.