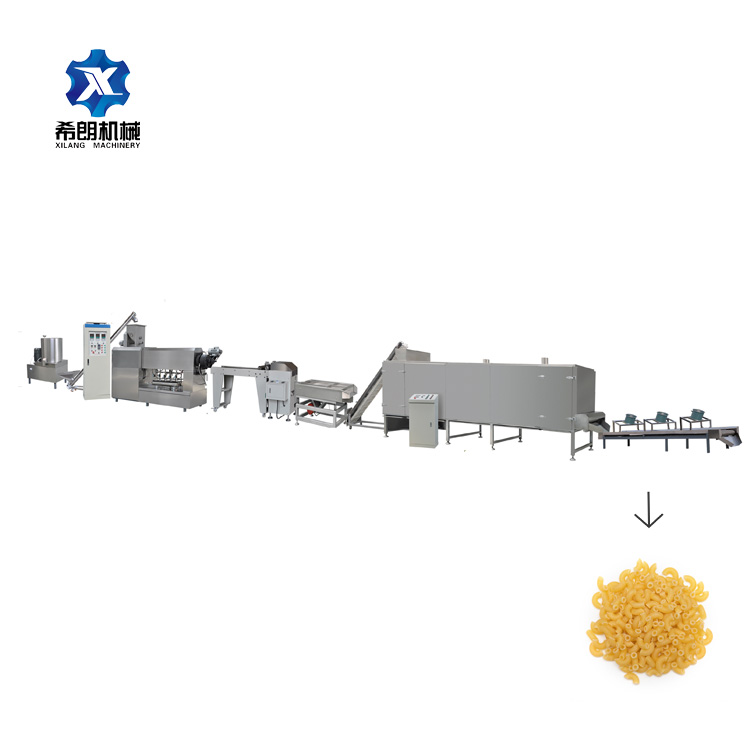

Multifunctional Industrial pasta macaroni production line

Brand :XI LANG

Product origin :Jinan,China

Delivery time :20days

Supply capacity : 100 sets per month

1. The production line has reasonable design, high degree of automation, extrusion parameters control, the main machine is equipped with high and low pressure screw, increase the use of raw materials, reduce the cost, improve the quality of products.

2. Adopt unique extrusion molding process, simple equipment, small investment. The product is natural in shape, delicate in texture and does not crack or come loose.

3. The host adopts advanced frequency conversion speed regulation technology, stable operation, less manual operation, safety and health, energy saving.

Brief introduction:

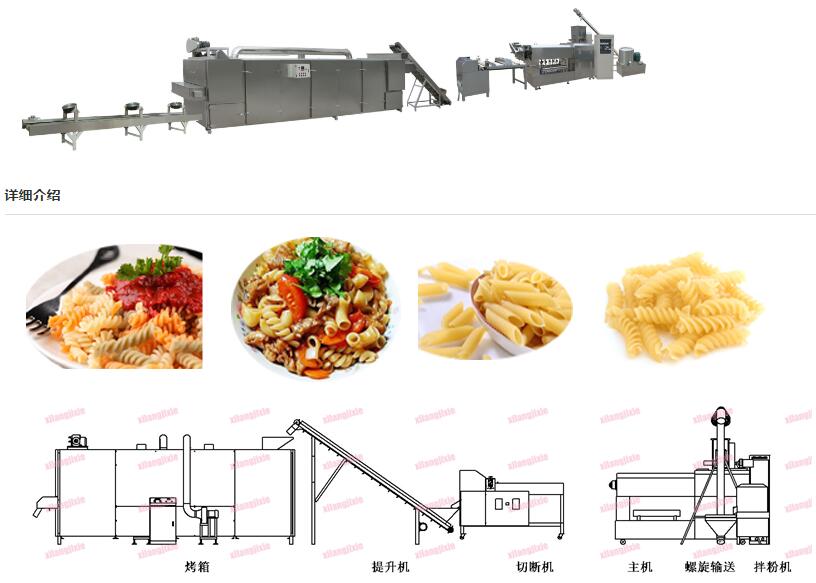

The macaroni production line mainly uses potato starch, corn starch, flour and so on as the raw material using the single screw extruder and the unique extrusion molding process, its biggest advantage is that it can change all kinds of moulds, extrusion different shapes of short Italian macaroni. Round tube, square tube, spiral, tube ring, butterfly, shell, letters, wheels and other colors.

Technical parameters:

Model | The main macine power | Output | The main machine size |

100 single screw production line | 45kw | 120-180kg/h | 2900*1000*1900mm |

75 twin screw production line | 90kw | 200-300kg/h | 5000*1200*2400mm |

Processing technology and equipment configuration:

I. Process flow of Italian spiral noodle production line:

Raw material preparation → mixing → feeding → extrusion molding → cutting → conveying → drying → cooling (packaging)

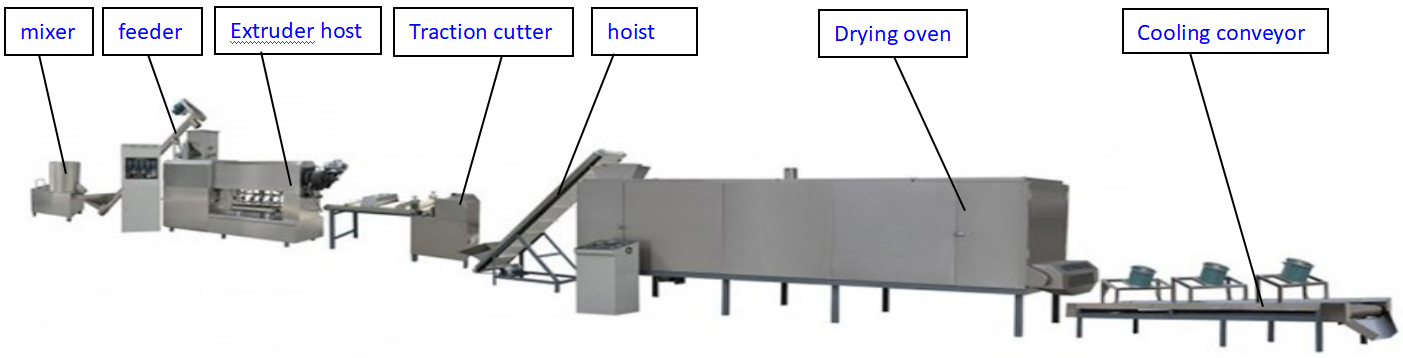

II. Equipment composition of Italian spiral noodle production line:

Powder mixing machine → screw feeding machine → single screw extruder → cutting machine → hoist → five layer five meters electric oven → cooling conveying → (packaging machine)

Technical formula and process composition:

1) Flour mixing machine: separate rice noodles or mix some additives, add a certain amount of water and mix well.

2) Feeding machine: The motor is used for screw conveying, and the mixed raw materials are conveyed to the feeding hopper of the extruder to ensure convenient and fast feeding.

3) Extruder: There is a special control cabinet, which can extrude rice particles in a high-pressure environment, adjust the process and change the mold to produce rice particles of different shapes.

4) Vibrating screen: The extruded particles contain a little temperature and viscosity, and the particles are spread out through the vibrating screen to avoid sticking together.

5) Air conveyor: convey the product to the oven, and the height of the hoist is determined according to the oven.

6) Multi-layer oven: most ovens are electric ovens, the temperature is adjusted between 0-200 degrees through the control cabinet, the inside is a stainless steel double-layer mesh bag, the baking time can be adjusted according to the speed, minus the particle moisture, and increase the shelf life ;

7) Cooling conveyor: the dried particles contain a certain temperature, and the packaging quality can be guaranteed by cooling to room temperature.

8) Packaging machine: vertical packaging machine and combined computer weighing and packaging machine can be used.

Samples and molds:

Company after-sales service commitment

1. The company's after-sales service personnel can provide ingredients and basic product formulas for related products.

2. On-site training of relevant personnel of the demanding party on equipment operation and regular maintenance.

3. Regular after-sales telephone return visits to customers to help you solve related difficult problems encountered in the use of the equipment.

4. Our company provides high-quality and low-cost spare parts to the buyer all the year round, and provides equipment upgrades and new product development support, so you really have no worries.

5. If the equipment is damaged due to the expiration of the warranty period, users in the province will arrive at the repair site within two days after receiving the notice from the buyer. Users outside the province negotiate with the technical staff to try to solve the problem as soon as possible.

Packing and transportation:

Company Profile:

Jinan Xilang Machinery Co., Ltd. is a professional manufacturer specializing in extrusion machinery, industrial microwave drying and sterilization equipment, and electromagnetic drying tunnel oven. The company is located in Jinan, the spring city of Shandong. The company has strong design strength, advanced production equipment, and rich manufacturing experience. Over the past eight years, through the continuous efforts of our company, we have good comments from domestic and abroad customers.

Our company is professional enterprise for producing extrusion machinery, twin-screw extruder, single-screw extruder, breakfast cereal instant food (corn flakes, nutritional powder) production line, leisure (fried, sandwich) snack food production line, pet feed, fishing feed production line, Tissue protein production line, modified starch production line, bread crumb production line, experimental twin-screw extruder, reconstituted nutritious rice production line, industrial microwave drying sterilization equipment, electromagnetic drying tunnel oven , packaging machinery and so on.

Motivation comes from a clear goal and wisdom comes from continuous learning. We always take high-tech products as the guide and high-quality service as our purpose, and wholeheartedly provide our users with first-class products, first-class quality and first-class service. Honesty and truth-seeking are our true qualities, and we are willing to innovate and develop together with everyone.

Common development, innovation and brilliance is our wish!