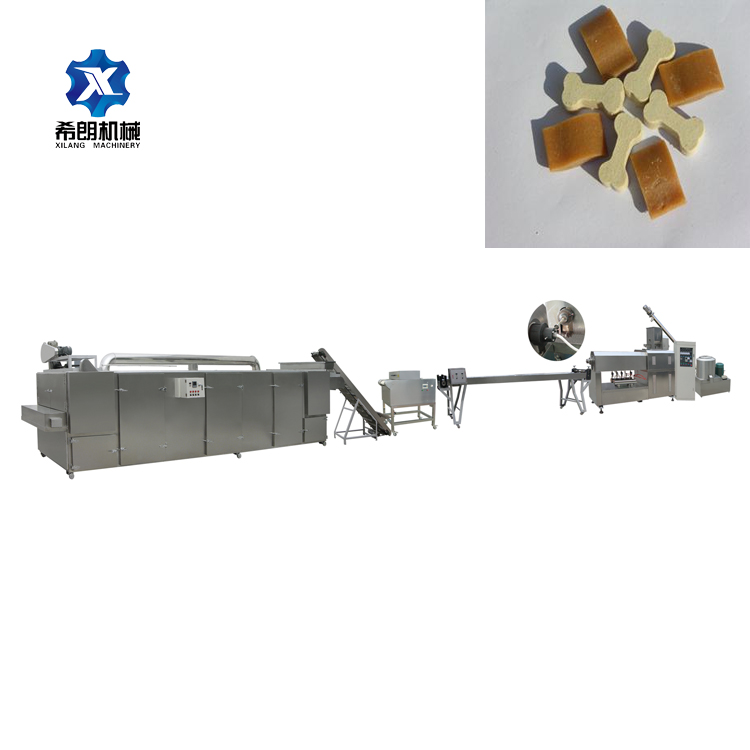

Single Screw Pet Dog Chews Snack Food Extruder

Brand :XI LANG

Product origin :Jinan,China

Delivery time :20days

Supply capacity : 100 sets per month

1 The feature of dog chew produced by our dog chews making equipment: strong teech,clean mouth and teeth. It can produce different shapes like twist,double colors,core filling and so on.

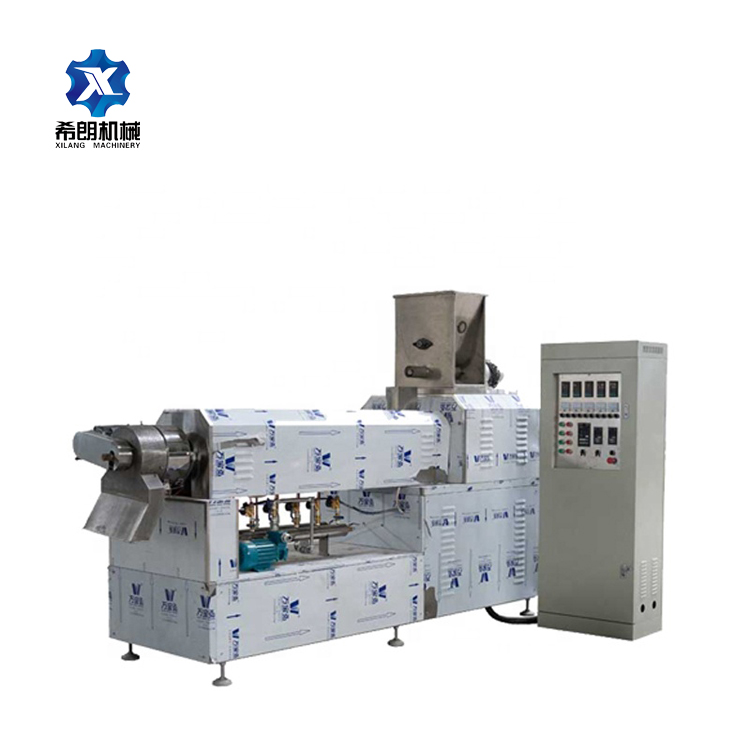

2 The screw material of dog treats machinery is 38CrMoAl which is wear-resisting.

3 The dog treat making equipment main body material is stainless steel, which is easy to be cleaned.

Dog Chews Snack Food Extruder

1.Brief introduction of dog chews making machinery:

Pet treats making machinery takes starch as raw materials with scientific configuration and was extruded from coextruder machine ,it can be made into many kind of shapes such as stick, bone ect.This kind of dog food not only provide protein fat vitamin nutrition for dogs, but also satisfy the dog nature hobby.It has following features: strengthen teeth, clean mouth and teeth, the products can be in many shapes, like twist, bi-color, core-filling and so on.The pet treats making machinery could produce single color pet chew and double colors pet chews.It could produce different shape products by using different moulds.

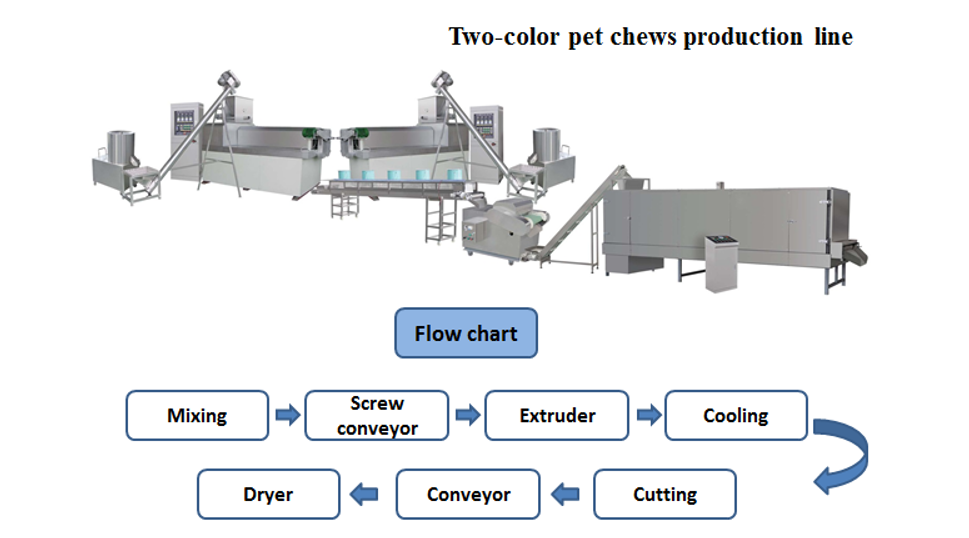

2.Process flow of pet chewing equipment:

raw material preparation → mixing → extrusion molding → cooling and conveying → cutting machine → conveying → drying → (packing)

Pet chewing equipment configuration:

powder mixer → extruder → Extruder → cooling conveyor → cutting machine → hoister → drying oven → (packing machine)

3.The technical specification of pet treats making machine:

Model | 65 twin screw extruder (dry type) | 70 twin screw extruder ( dry type) | 70 twin screw extruder (wet type) | 75 twin screw extruder (dry type) | 95 twin screw extruder(dry type) |

The power of main machine | 22kw | 30kw | 37/45 | 55/75 | 90/110 |

Drying type | gas/electric | gas/electric | gas/electric/Steam | gas/electric/Steam | gas/electric/Steam |

Production capacity | 120-150kg/h | 150-180kg/h | 350-400kg/h | 600-800kg/h | 1000-1200kg/h |

Appearance size | 12000x4000x2200mm | 13500x4000x2200mm | 16500x4000x3200mm | 18500x4000x3200mm | 21000x4000x3200mm |

4. Dog chews samples:

5.Process composition of pet chew production line

5.1. raw materials: all kinds of meat raw powder and glue powder are mixed evenly, and the water content is adjusted.

5.2. Raw material conveying: stainless steel conveyor automatically transfer the material to the screw extruder

5.3. Extrusion : The extrusion producing belongs to hot extrusion, but the extrusion temperature can be freely controlled, so the organizational structure, expansion degree, and hardness can be freely controlled.

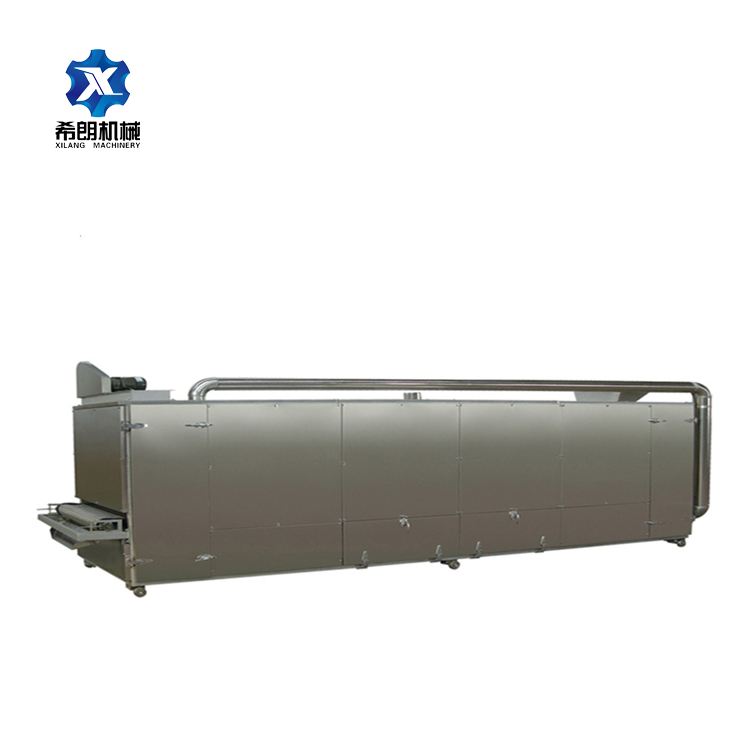

5.4. Cooling: As the dog chew pellets are hot extrusion, the temperature after being formed from the extruder is relatively high, and cooling is required to reduce the overall temperature of the inside and outside of the pellets to normal temperature. Guarantee storage and sale.

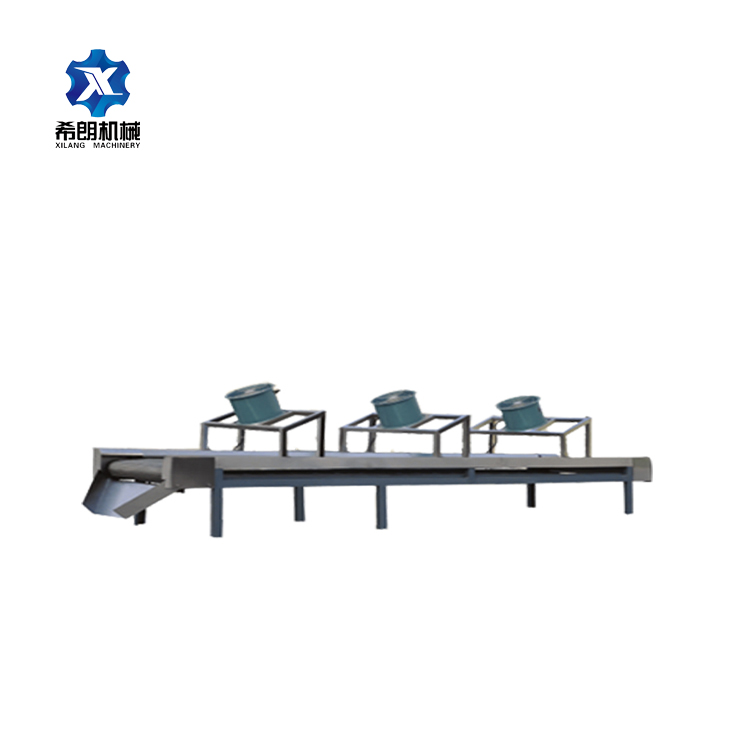

5.5. Cutting and forming: Cut the cooled long rubber chew stick into chew particles with uniform length. The length of the particles can be freely controlled by adjusting the cutting speed.

5.6. Conveyor: convey the chew to the oven,

5.7. Multi-layer oven: The oven is mostly electric oven, the temperature is adjusted between 0-200 degrees through the control cabinet, the inside is stainless steel double-layer mesh bag, which reduces the moisture of chew particles, promotes the curing rate, and increases the shelf life.

5.8. Cooling conveyor: cooling to room temperature for easy packaging.

6.Sample pictures

7.Quality Assurance:

1. The technology department of the company constantly develops and innovates according to market demand, and improves and upgrades the equipment according to customer demand.

2. Acceptance of equipment and spare parts.

Full-time quality control personnel to carry out batch inspection of external parts and external parts, and to carry out quality inspection of key precision parts.

8.Packing and Delivery:

1.Packaging: All dog chews making machinery are packaged according to international standard export package.Inside is covered by plastic film, outside is wooden case.

9.Company Profile:

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

10.FAQ

1. What's the pre-sale service of your company for pet chews making machinery?

Related machines’s technical parameter will be supplied to customer.

1.1 Layout can be provided in advance basing on customer’s factory size.

1.2 General formulation can be offered according to customer’s material cost,.

1.3 Machine could be customization.

1.4 Professional suggestion for Market, machines, processing , materials, packing.

1.5 Suggesting professional ship agent or helping book ship according to customer situation.

2. What's the after-sale service of your company for pet chews making machinery?

2.1. Allocation chart will be offered as the buyer’s request .

2.2. Professional Operation manual will be supplied after shipment.

2.3. One year warranty support, life time maintenance with cost price.

2.4. Free easy broken spare parts will be sent together with machines .

2.5. First installation supports.

2.6. Worker training supports.

3. what about spare parts after sale service for pet chews making machinery?

We can offer the wearing parts all the time together with changing video.

We are the manufactuer,welcome to visit us.

Yes, we could print your logo on both products and packages.