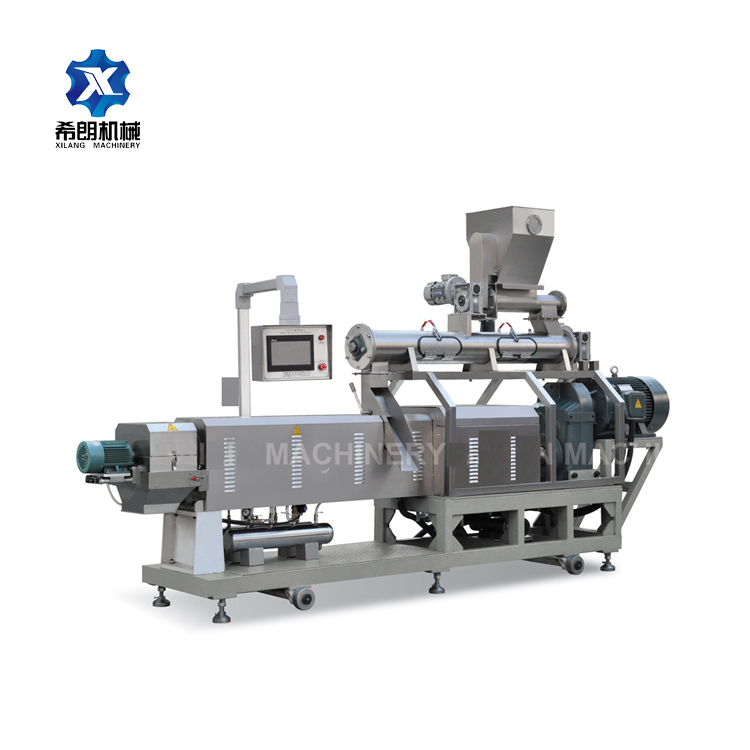

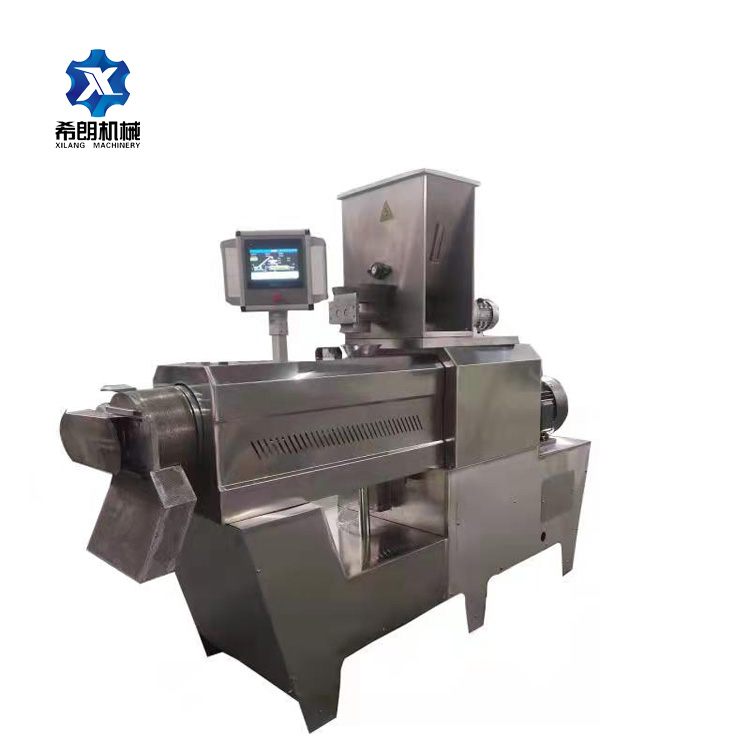

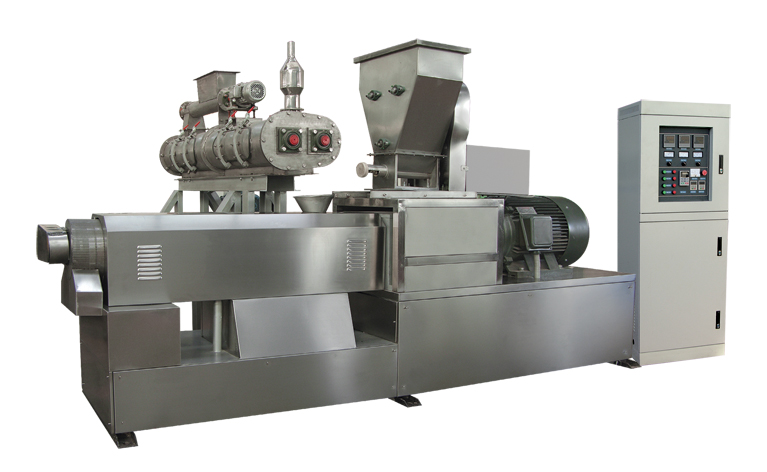

Multifunction Twin Screw Extruder Machine

Brand :XI LANG

Product origin :Jinan, China

Delivery time :20 days

Supply capacity : 100 sets per month

1.The screws of extruder material is 38CrMnAl, which is wear-resisting.

2.The processing line has self-cleaning function.

3.The main body material is stainless steel, which is easy to be cleaned.

4.Guarantee time is 2 year.

5.Converter(used to control the speed of feeding system,cutting system and control system,can protect of the motor)use the brand of Delta,Pioneer,CHNT or Schneider.

6.After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

Twin Screw Extruder Machine

Multifunction Twin Screw Extruer Introduction

It can be widely used in producing snack food, cereals, corn flakes, pet food, dog food, fortified rice, soya protein food and so on.

Specification

1.1 Twin-screw extruder adopts variable-frequency regulating speed technology, which can supply more power, operate more steadily, but less energy consumption.

1.2 The screws adopt nitriding alloy steel, which make them longer life. Some extruders' screws adopt building composite structures. It can be combined discretionarily according to different requirement.

1.3 Twin-screw extruders are equipped with forced lubricating system, to make sure drive system has long life.

1.4 Twin-screw extruders are equipped with full automatic visible temperature control system.

1.5 Twin-screw extruders have self-cleaning function, don't need to disassemble screws to clean.

1.6 There are different screws and die molds for different food.

1.7 Twin-screw extruders have wide material range, multi-shape products and flexible collocations.

2. The main body material is stainless steel, which is easy to be cleaned.

3.The screws material is 38CrMoAl, which is wear-resisting.

Working principle of twin screw extruder

Twin screw extruder is composed of feeding, extrusion, heating, rotary cutting and other parts.

Powdery raw materials through the extrusion machine, from powdery into paste, under the action of strong pressure difference, become paste material by the die hole ejection moment, the formation of loose structure of extrusion products.

The chamber of the extruder adopts multi-block type, each chamber can control the temperature independently, and the temperature is automatically controlled to ensure the taste and quality of the product.

Technical parameters of twin screw extruder

Modle | Installed Power | Power Consumption | Throughput | Dimension(mm) |

XL65-Ⅱ Processing Line | 35kw | 28kw | 120~150kg/h | 2400x1000x800 |

XL70-Ⅱ Processing Line | 45kw | 40kw | 150~200kg/h | 2600x1000x1800 |

XL75-Ⅳ Processing Line | 85kw | 70kw | 500~800kg/h | 4500x1200x1800 |

XL85-Ⅱ Processing Line | 80kw | 70kw | 300~500kg/h | 3700x1200x3000 |

XL95-Ⅱ Processing Line | 110~130kw | 90~110kw | 800~1200kg/h | 4500x1200x2600 |

XL32 Processing Line | 12kw | 8kw | 10~15kg/h | 2000x600x1500 |

1. Free consulting services, equipment services, installation and debugging, training services;

2. Responsible for personnel training and guidance services;

3. One year free warranty for the equipment.

4. Provide customers with production line layout and placement services, and provide detailed plans according to customers' plant or actual situation.

5. According to the size of the workshop provided by the customer, the engineer will design and configure the machine for free.

Packing and transportation

1.Packaging: All machines are packaged according to international standard export package.Inside is covered by plastic film, outside is wooden case.

2.Shipping: 15-35 working days after receiving deposit.

COMPANY PROFILE

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

FAQ

1. What's the pre-sale service of your company for extruder machine ?

Related machines’s technical parameter will be supplied to customer.

1.1 Layout can be provided in advance basing on customer’s factory size.

1.2 General formulation can be offered according to customer’s material cost,.

1.3 Machine could be customization.

1.4 Professional suggestion for Market, machines, processing , materials, packing.

1.5 Suggesting professional ship agent or helping book ship according to customer situation.

2. What's the after-sale service of your company for extruder machine?

2.1. Allocation chart will be offered as the buyer’s request .

2.2. Professional Operation manual will be supplied after shipment.

2.3. One year warranty support, life time maintenance with cost price.

2.4. Free easy broken spare parts will be sent together with machines .

2.5. First installation supports.

2.6. Worker training supports.

3. what about spare parts after sale service for extruder machine?

We can offer the wearing parts all the time together with changing video.

4 Are you manufacturer or trading company?

We are the manufactuer,welcome to visit us.

5 Whether you could make your brand on the products?

Yes, we could print your logo on both products and packages.

6 What is the terms of payment?

30% T/T in advance, the balance before goods leave our company.