-

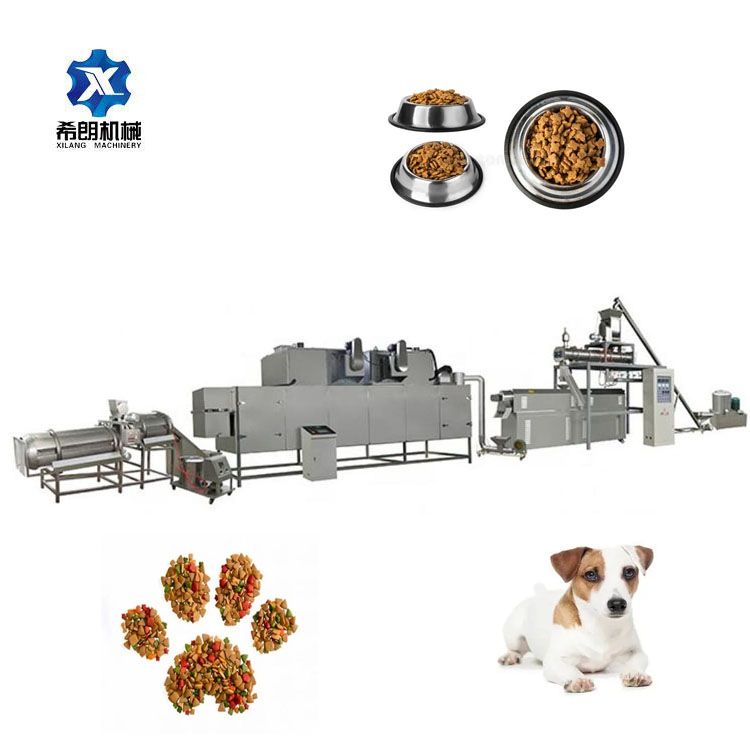

Pet food production line dog food making machine cat food processing line

1.The dog food pellet extrusion machine manufacturing equipments adopt internationally advanced twin screw extrusion technology. 2.The dog food pellet extrusion machine manufacturing equipments have advantages of small investement,high output ,small floor area etc.

Read More -

Higher capacity Fried Instant Noodles Making Machinery hot sale in food factory

1. Xilang small instant noodle production line has novel design, compact structure, perfect technology and stable and reliable performance. Moderate production capacity, small footprint, small investment. 2. The mini instant noodle making machine from flour to finished product is completed at one time, with high degree of automation and easy to learn. 3. The mini instant noodle processing machine has some advantages: short rehydration time, good elasticity, smooth and transparent, the quality of corrugated instant noodles can be comparable with that of traditional large-scale equipment products.

Read More -

Industrial 20000pcs/8h capacity Fried Instant Noodles Making Machinery hot sale in food factory

1. Xilang small instant noodle production line has novel design, compact structure, perfect technology and stable and reliable performance. Moderate production capacity, small footprint, small investment. 2. The mini instant noodle making machine from flour to finished product is completed at one time, with high degree of automation and easy to learn. 3. The mini instant noodle processing machine has some advantages: short rehydration time, good elasticity, smooth and transparent, the quality of corrugated instant noodles can be comparable with that of traditional large-scale equipment products.

Read More -

20000pcs/8h capacity Fried Instant Noodles Making Machinery hot sale in food factory

1. Xilang small instant noodle production line has novel design, compact structure, perfect technology and stable and reliable performance. Moderate production capacity, small footprint, small investment. 2. The mini instant noodle making machine from flour to finished product is completed at one time, with high degree of automation and easy to learn. 3. The mini instant noodle processing machine has some advantages: short rehydration time, good elasticity, smooth and transparent, the quality of corrugated instant noodles can be comparable with that of traditional large-scale equipment products.

Read More -

Industrial small scale Fried Instant Noodles Making Machinery hot sale in food factory

1. Xilang small instant noodle production line has novel design, compact structure, perfect technology and stable and reliable performance. Moderate production capacity, small footprint, small investment. 2. The mini instant noodle making machine from flour to finished product is completed at one time, with high degree of automation and easy to learn. 3. The mini instant noodle processing machine has some advantages: short rehydration time, good elasticity, smooth and transparent, the quality of corrugated instant noodles can be comparable with that of traditional large-scale equipment products.

Read More -

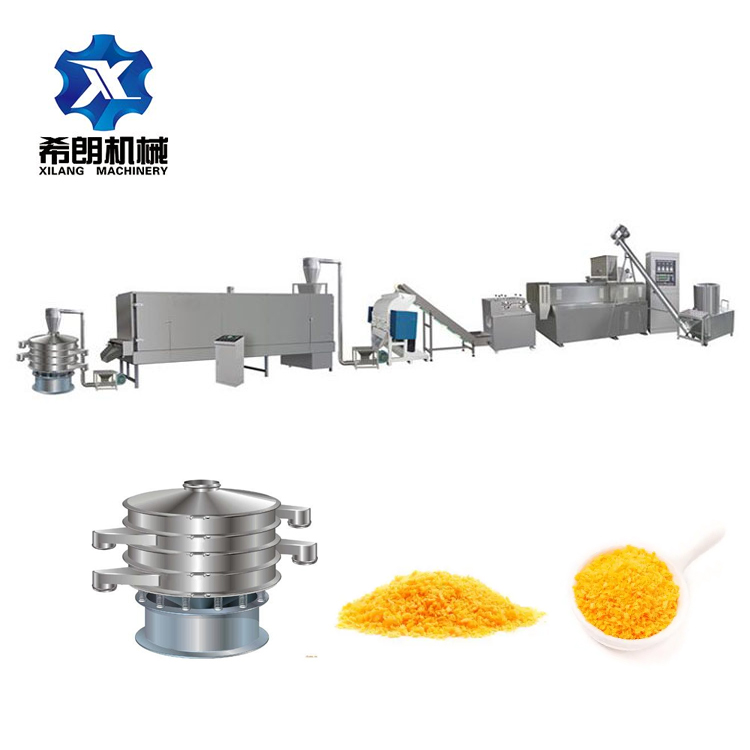

Industrial various shapes of bread crumbs production line puffed crumbs making machine

1. The production process is fully automatic line from powder material to last product forming. 2.The advantage of the line : fewer worker investment; repeated use of raw materials, no waste;high efficiency and energy saving and lower manufacturing cost. 3. The bread crumb line is multi-functional line which can produce a variety of shapes of bread crumb like bread bran, needle, granular, snowflake, flake, star shape and other shapes. 4. the basic raw materials are more extensive, corn, rice, millet, wheat, flour, starch and other grains are applicable.

Read More -

Puff bread crumb extruder making machine bread crumb production line

1. The production process is fully automatic line from powder material to last product forming. 2.The advantage of the line : fewer worker investment; repeated use of raw materials, no waste;high efficiency and energy saving and lower manufacturing cost. 3. The bread crumb line is multi-functional line which can produce a variety of shapes of bread crumb like bread bran, needle, granular, snowflake, flake, star shape and other shapes. 4. the basic raw materials are more extensive, corn, rice, millet, wheat, flour, starch and other grains are applicable.

Read More -

Industrial Bread crumb procution line popular used in the fried food

1. The production process is fully automatic line from powder material to last product forming. 2.The advantage of the line : fewer worker investment; repeated use of raw materials, no waste;high efficiency and energy saving and lower manufacturing cost. 3. The bread crumb line is multi-functional line which can produce a variety of shapes of bread crumb like bread bran, needle, granular, snowflake, flake, star shape and other shapes. 4. the basic raw materials are more extensive, corn, rice, millet, wheat, flour, starch and other grains are applicable.

Read More -

2024 Industrial high capacity bread cake crumb extruder making machine production line

1. The production process is fully automatic line from powder material to last product forming. 2.The advantage of the line : fewer worker investment; repeated use of raw materials, no waste;high efficiency and energy saving and lower manufacturing cost. 3. The bread crumb line is multi-functional line which can produce a variety of shapes of bread crumb like bread bran, needle, granular, snowflake, flake, star shape and other shapes. 4. the basic raw materials are more extensive, corn, rice, millet, wheat, flour, starch and other grains are applicable.

Read More -

Semi-auto bread cake crumb extruder making machine production line

1. The production process is fully automatic line from powder material to last product forming. 2.The advantage of the line : fewer worker investment; repeated use of raw materials, no waste;high efficiency and energy saving and lower manufacturing cost. 3. The bread crumb line is multi-functional line which can produce a variety of shapes of bread crumb like bread bran, needle, granular, snowflake, flake, star shape and other shapes. 4. the basic raw materials are more extensive, corn, rice, millet, wheat, flour, starch and other grains are applicable.

Read More -

automatic bread cake crumb extruder making machine production line

1. The production process is fully automatic line from powder material to last product forming. 2.The advantage of the line : fewer worker investment; repeated use of raw materials, no waste;high efficiency and energy saving and lower manufacturing cost. 3. The bread crumb line is multi-functional line which can produce a variety of shapes of bread crumb like bread bran, needle, granular, snowflake, flake, star shape and other shapes. 4. the basic raw materials are more extensive, corn, rice, millet, wheat, flour, starch and other grains are applicable.

Read More -

Industrial price-friendly small scale Fried Instant Noodles Making Machinery

1. Xilang small instant noodle production line has novel design, compact structure, perfect technology and stable and reliable performance. Moderate production capacity, small footprint, small investment. 2. The mini instant noodle making machine from flour to finished product is completed at one time, with high degree of automation and easy to learn. 3. The mini instant noodle processing machine has some advantages: short rehydration time, good elasticity, smooth and transparent, the quality of corrugated instant noodles can be comparable with that of traditional large-scale equipment products.

Read More

- Home >

- Products

Get the latest price? We'll respond as soon as possible(within 12 hours)