-

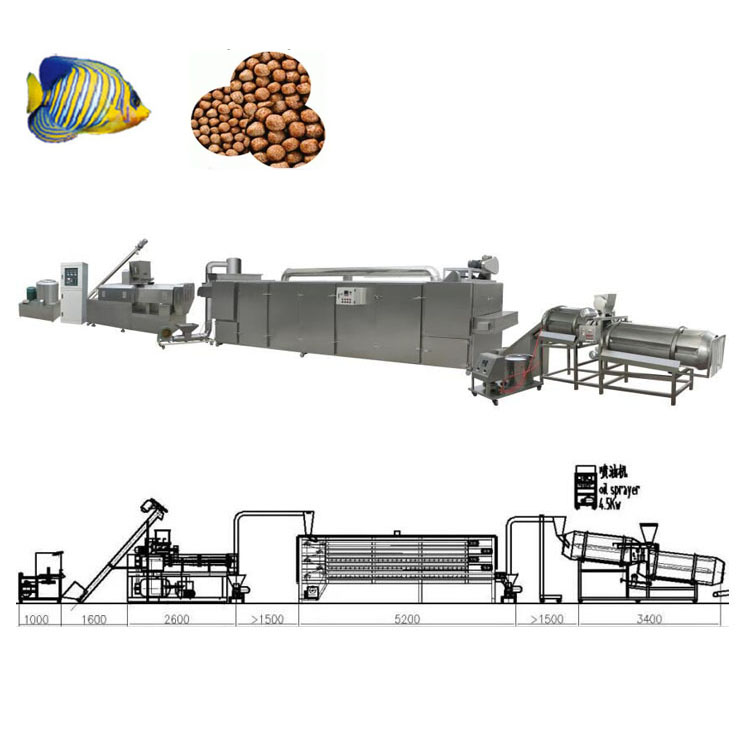

fish food making machine production line

The fish food making machine production line has some advantages: 1.small investment, high output, small area space. 2.The whole machine is processed with stainless steel materials. 3.The production line adopts internationally advanced twin-screw extrusion technology.

Read More -

ornamental fish feed machine extruder

1.The ornamental fish feed machine line adopts international advanced twin-screw extrusion technology, with small investment, high output and small occupation area. 2.The fish feed manufacturing machine extruder is suitable for different growth stages of fish food. Change molds to make different shapes of fish food. 3.Adjust the raw material, temperature, moisture and other technological parameters, so that the product has the characteristics of novel shape, unique texture, rich nutrition, delicate organization etc.

Read More -

floating fish feed processing machine line

1.The floating fish feed processing machine line can make kinds of feed for different fish, such as fish, catfish, shrimps, crab, etc. 2.Extruder for fish feed production process is deliberately made for special feed, which needs high in-shape rate and good-looking appearance. 3.High Efficiency,the floating fish feed processing machine line Low electricity and labor consumption,

Read More -

puffed floating fish feed making machine

1.Double screw extrusion technology to produce pet food, can retain the nutrition ingredients in the formula raw materials, easy to digest and absorb, the formula shape is easy to change; 2.Optimized configuration of the whole assembly line, high degree of automation, precise control of the production process, stable product quality, high production efficiency, health and environmental protection;

Read More -

Full Automatic Best Price Pet Food Processing Equipment Making Machinery

The screw material of pet feed pellet production line is 38CrMoAL.Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials. The parts of pet food extruder machine adopt famous brand Pet food processing machine adopt advanced twin screw extrusion technology Pet feed production line accept OEM/ODM service

Read More -

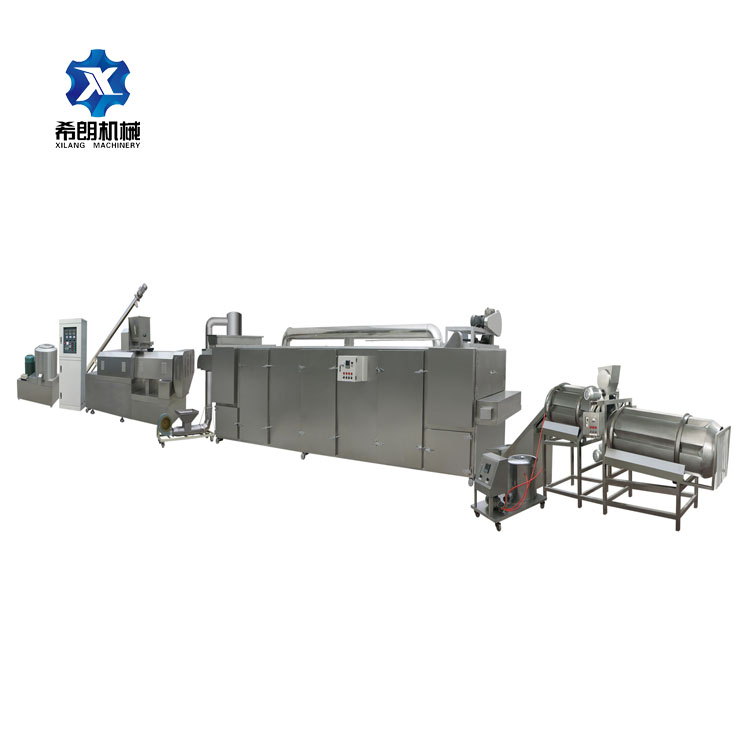

dog and cat food making machine extruder

1.Technology: Xilang cat feed production line adopts advanced twin screw extrusion technology, reasonable design, high degree of automation, stable performance, easy operation. 2.Product: novel shape, unique taste, rich nutrition, easy to digest, more suitable for pet food needs. 3.Selection: The pet food production line output: 140-160kg/h,240-260kg/h,500-600kg/h can be reasonably configured according to customer needs.

Read More -

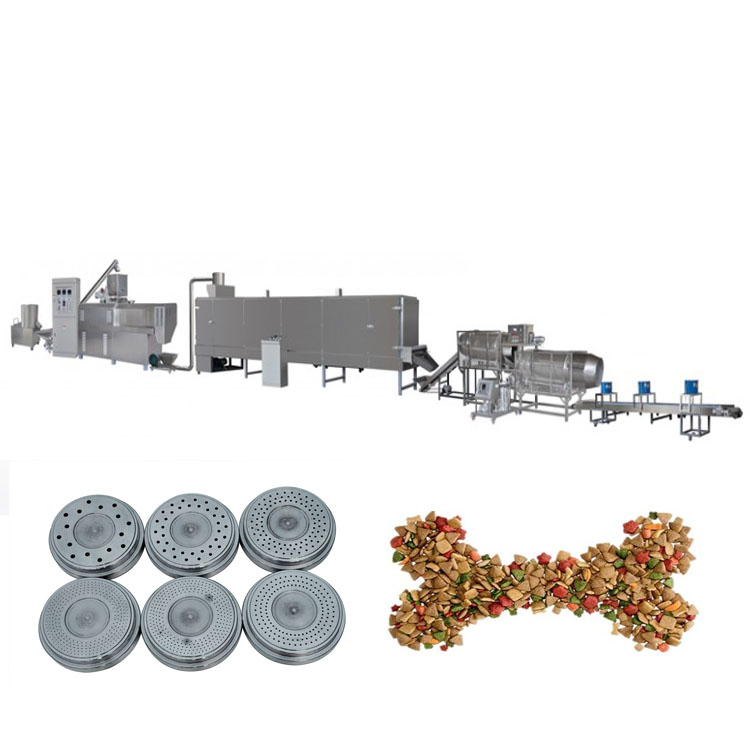

dog and cat food making machine line

1.dog and cat food making machine line adopts twin screw extrusion technology. 2.The whole dog and cat food making machine line is made up of Mixing system, Extrusion system, Drying system and Flavoring system. 3.The dog and cat food making machine line is multi-function machine line, which not only can produce various animal feeds,Also can be used for producing both floating and sinking fish feed .

Read More -

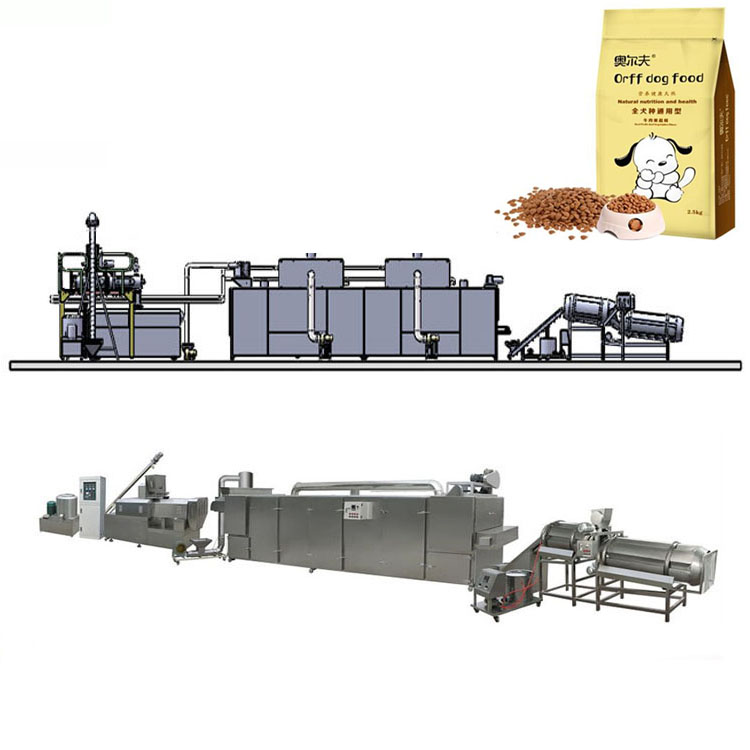

dog food pellet extrusion machine manufacturing equipment

1.The dog food pellet extrusion machine manufacturing equipments adopt internationally advanced twin screw extrusion technology. 2.The dog food pellet extrusion machine manufacturing equipments have advantages of small investement,high output ,small floor area etc.

Read More -

dog food pellet equipment producing machine line

1.The control parameters of the equipment are accurate and easy to operate. which ensured the pet feed products be completed in specific temperature, pressure, humidity and time. 2.Feeding, rotary cutting, main drive motor adopts frequency conversion speed regulation, stable operation, strong power, energy saving and low noise

Read More -

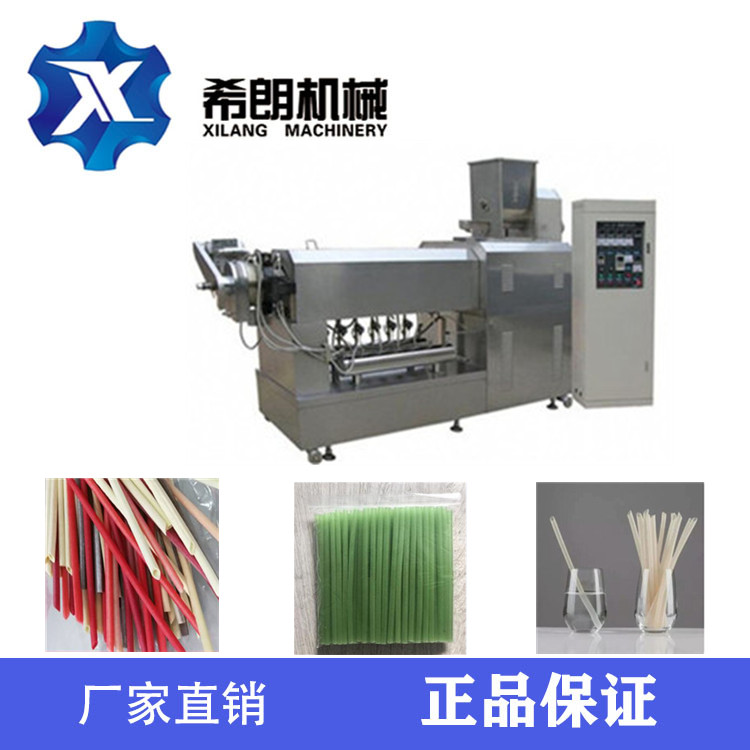

Twin screw extruder for Degradable tableware Edible Rice Drinking Straw Production Line

1. Technology: Xilang rice straw production line has reasonable design, high degree of automation, accurate extrusion parameters control, the host is equipped with high and low pressure screw, which increases the use of raw materials and reduces the cost. The product quality is higher, the variety is more diverse. 2. Process: The production process is simple, a twin screw puffing machine can complete the process of mixing and rubbing, cooking, extrusion molding, made of various sizes of billets, and then drying can be made into smooth surface, realistic shape straw; 3. Products: by adjusting the forming mold and ingredients, edible straws with novel shapes and rich colors can be produced. The appearance of the straw is not different from ordinary straw, the surface is sandy texture, strong and flexible.

Read More -

Degradable tableware Edible Rice Drinking Straw Production Line Fully automatic

1. Technology: Xilang rice straw production line has reasonable design, high degree of automation, accurate extrusion parameters control, the host is equipped with high and low pressure screw, which increases the use of raw materials and reduces the cost. The product quality is higher, the variety is more diverse. 2. Process: The production process is simple, a twin screw puffing machine can complete the process of mixing and rubbing, cooking, extrusion molding, made of various sizes of billets, and then drying can be made into smooth surface, realistic shape straw; 3. Products: by adjusting the forming mold and ingredients, edible straws with novel shapes and rich colors can be produced. The appearance of the straw is not different from ordinary straw, the surface is sandy texture, strong and flexible.

Read More -

Single screw Macaroni Italy pasta Making Machine Production Line

1. Jinan Xilang macaroni machine equipment production line, through the replacement of different molding mold and cutting system, can produce a variety of shapes of pasta products, products natural realistic texture fine, loose taste, not cracked. 2. The production line has reasonable design, strong stability and high degree of automation. The main machine is equipped with high and low pressure screw, which increases the scope of application of raw materials, reduces the cost and improves the quality of products. 3. The host adopts advanced frequency conversion speed regulation technology, precise extrusion parameter control, stable product quality, simple operation, high efficiency and energy saving.

Read More

- Home >

- Products

Get the latest price? We'll respond as soon as possible(within 12 hours)